Search Results

- IDNO:

- 003046

- Title:

- Jeffrey 290 cutting trench for 2200 volt line at Jamison No. 9

- Description:

- Jeffrey 290 cutting trench for 2200 volt line at Jamison No. 9. Stonega Coke and Coal.

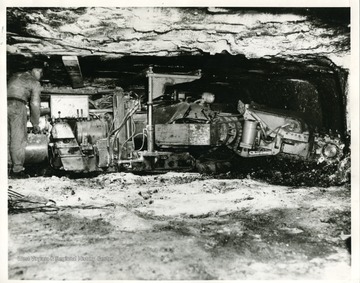

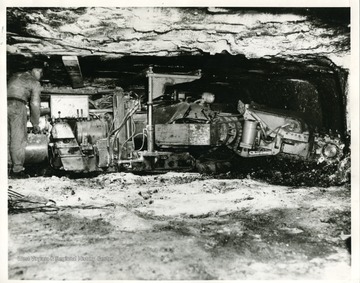

- IDNO:

- 003047

- Title:

- Miner Operating a Loading Machine at Jamison No. 9

- Description:

- Miner using a 11 BU loading machine at Jamison No. 9. Stonega Coke and Coal.

- IDNO:

- 003048

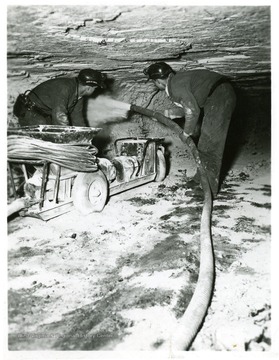

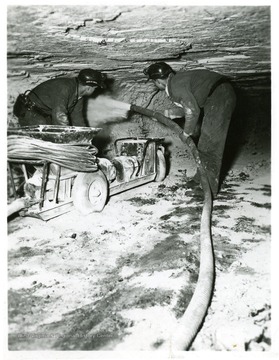

- Title:

- Joy 10 RU Preparing to Cut US Royal Cable at Jamison No. 9

- Description:

- A Joy 10 RU preparing to cut US Royal Cable at Jamison No. 9. Stonega Coke and Coal.

- IDNO:

- 003049

- Title:

- Miner Operating a Cutting Machine

- Description:

- 'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and placed in cutting position as you see in this picture. The machine consists of an endless chain with bits inserted, which act as cutters. The machine cuts a kerf or hole along the bottom of the coal about 4 feet and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as bug dust. Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

- IDNO:

- 003050

- Title:

- Continuous Mining Machine

- Date:

- undated

- Description:

- Miner running a continuous mining machine.

- IDNO:

- 003051

- Title:

- Rock Dusting at Consol. Mine No. 207

- Description:

- Two miners dust the rocks at Consol Mine No. 207 for safety.

- IDNO:

- 003052

- Title:

- Loading Machine and Shuttle Car at Jamison No. 9

- Description:

- An 11BU loading machine and a Joy Shuttle car at Jamison No. 9. Stonega Coke and Coal.

- IDNO:

- 003053

- Title:

- Sewall Coal Seam Worked by the New River Coal Company

- Description:

- 'All White Oak mines work the same seam of coal, viz: Sewall...The face of one of the working places or rooms is shown in this picture. The coal averages about 48 to 50 inches in thickness. This working place is now ready to be cut by the undercutting machine, so it can be shot down by the miner and loaded into the cars for transportations to the tipple. The white line on the roof in this picture is the center line of the room set by the engineers to guide the men operating the mining machine in driving the room straight.'

- IDNO:

- 003054

- Title:

- Drilling Machine at Jamison No. 9

- Description:

- Miner with drilling machine at Jamison No. 9.

- IDNO:

- 003055

- Title:

- Miners Operating Shuttle Cars

- Description:

- 'Shuttle Cars: Here are pictured loaded and empty shuttle cars sometimes called buggies. Note the noveyor on the bottom of the empty car for unloading the coal at a central loading station, into the mine cars. This equipment is propelled by huge batteries or electric cable and of course requires no track. Track-mounted mechanical loaders load directly into the mine car.'

- IDNO:

- 003056

- Title:

- Continuous Mining Machine, Helper and Crew

- Description:

- 'Machine, helper and crew. 350 tons a day, per 8 hour shift.'

- IDNO:

- 003057

- Title:

- Dogs in Harness, Ohio Coal Mine

- Date:

- ca. 1890

- Description:

- Two dogs harnessed to coal carts. About 1890, Ohio Coal Mine. This photograph is the property of Pittsburgh Consolidation Coal Co.