Search Results

- IDNO:

- 002679

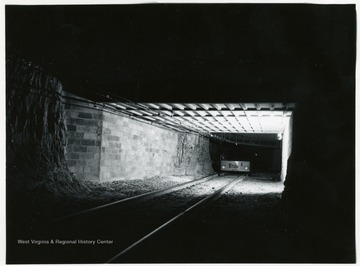

- Title:

- Overcast in Jamison No. 9 Mine Shaft Bottom

- Description:

- Overcast, where two air currents cross in a mine, at the Jamison Mine No. 9 shaft bottom.

- IDNO:

- 002680

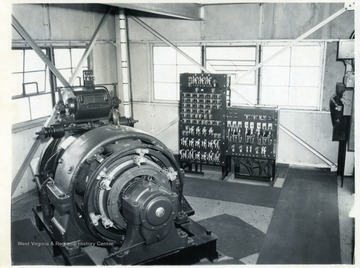

- Title:

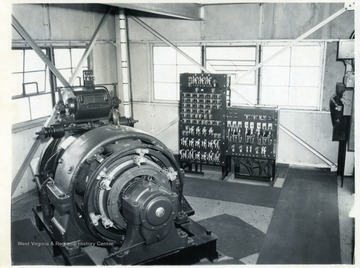

- Elevator Controls at the Jamison No. 9 Mine

- Description:

- Controls at the Jamison No. 9 Mine.

- IDNO:

- 002681

- Title:

- Elevator Controls at the Jamison No. 9 Mine

- Description:

- Controls at the Jamison No. 9 Mine.

- IDNO:

- 002682

- Title:

- Elevator Controls at the Jamison No. 9 Mine

- Description:

- Controls at the Jamison No. 9 Mine.

- IDNO:

- 002683

- Title:

- Coal Shuttle in Jamison Mine No. 9

- IDNO:

- 002684

- Title:

- Mine Car

- Description:

- Mine car traveling through the mine.

- IDNO:

- 002685

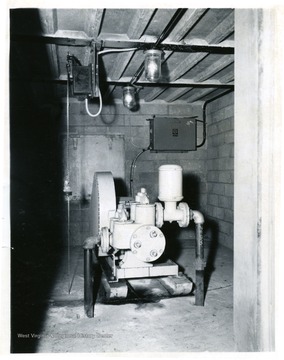

- Title:

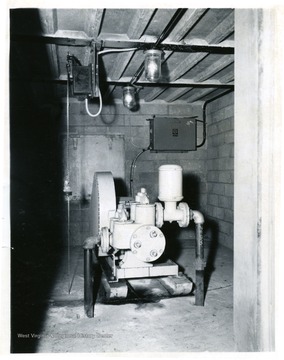

- Diaphram Pump at Jamison Mine No. 9

- IDNO:

- 002686

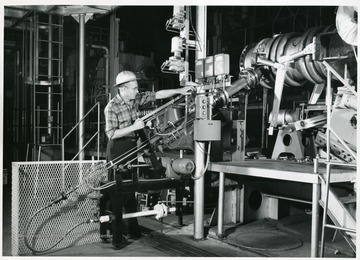

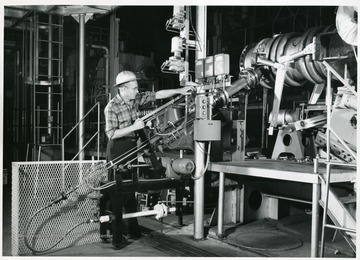

- Title:

- Sampling Hot Ash-Laden Gas

- Date:

- ca. 1960-1970

- Description:

- 'A small portion of the hot ash-laden gas stream entering the turbine is continuously removed by this ash-sampling unit. Data from the operation of this unit is analyzed to determine the concentration, size, and composition of the ash in the hot gases entering the turbine.'

- IDNO:

- 002687

- Title:

- ITE Circuit Breaker at Jamison Mine No. 9

- IDNO:

- 002688

- Title:

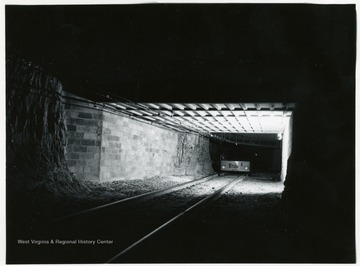

- Rock Dusted Mine Shaft at Jamison No. 9

- Description:

- Jamison No. 9 Mine shaft with a tensioning device on a cable.

- IDNO:

- 002689

- Title:

- Inter-Floor Lift at Jamison Mine No. 9

- IDNO:

- 002690

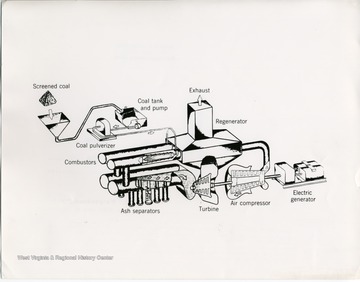

- Title:

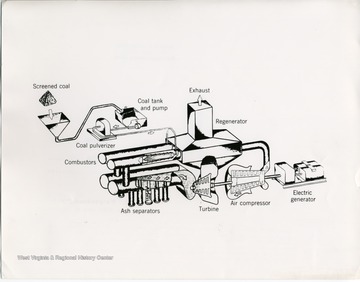

- Schematic Diagram of Coal-Fired Gas Turbine

- Date:

- ca. 1960-1970

- Description:

- Coal crushed to 3/16-inch by 0 is pumped to a pulverizer that grinds it to 90-per cent hrough 200-mesh. The product is mixed with air and burned in the combustors. Hot high-speed gas from the ash separators drives the turbine, air compressor, and electric generators. Exhaust from the turbine passes through a regenerator that preheats compressed air to the combustors. If used, please credit Bureau of Mines, U.S. Department of the Interior.