Search Constraints

« Previous |

1 - 96 of 166

|

Next »

Search Results

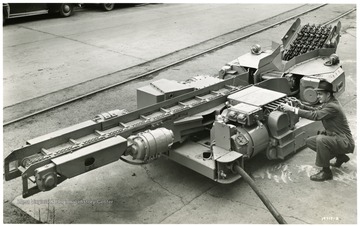

IDNO:

001859

Title:

Joy Manufacturing Company Continuous Mining Machine

Description:

A man inspecting a Joy Continuous Miner.

IDNO:

001860

Title:

Joy Manufacturing Company Continuous Mining Machine

Description:

View of a Joy Continuous Mining machine.

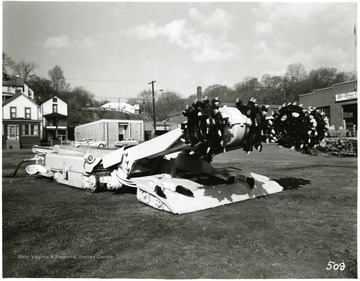

IDNO:

001873

Title:

Continuous Mining Machine

Description:

A Continuous Mining Machine on display above ground.

IDNO:

001874

Title:

Joy Manufacturing Company Continuous Mining Machine

Description:

A Joy Manufacturing Co. Continuous Mining Machine. ML 5196 DIO57.

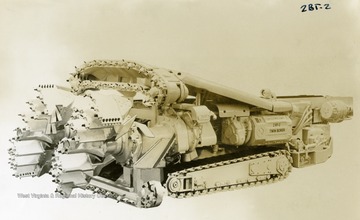

IDNO:

001877

Title:

Continuous Mining Machine, Joy Manufacturing Company

Description:

A continuous miner, model 2BT-2 Twin Borer, sits on display.

IDNO:

001879

Title:

Joy Manufacturing Company Executives Examine a Joy Continuous Mining Machine

Description:

Joy executives stand beside a continuous mining machine.

IDNO:

001880

Title:

Manufacturer's Photo of a Coal Loading Machine

IDNO:

001907

Title:

Marietta Miner Continuous Mining Machine

Description:

A large Marietta Miner Continuous Mining Machine.

IDNO:

001914

Title:

Joy Manufacturing Company Continuous Mining Machine

Date:

1957

Description:

Man operating a JMC1 continuous miner.

IDNO:

001915

Title:

Continuous Mining Machine

Description:

Two men standing next to a continuous mining machine.

IDNO:

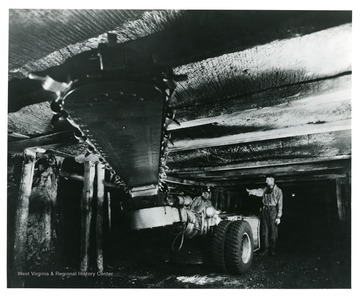

002111

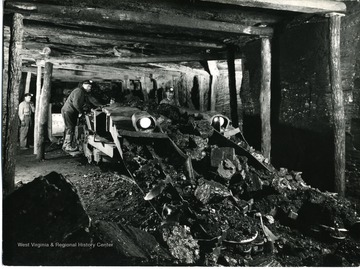

Title:

Continuous Mining Machine in Operation in a Four Foot Seam

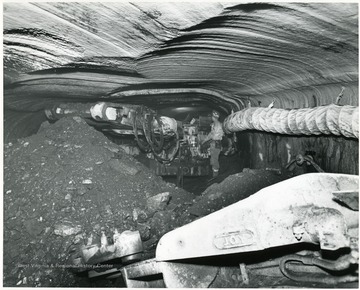

Description:

A continuous mining machine operating in a four foot seam.

IDNO:

002121

Title:

Lee Norse CM28E Continuous Miner

Description:

Continuous miner in action.

IDNO:

002136

Title:

Drilling Prior to Placing Charges

Description:

Two men using large bits to drill prior to placing charges.

IDNO:

002141

Title:

Coal Loading Machine

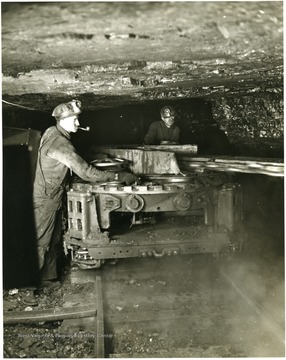

IDNO:

002149

Title:

Coal Loading Machine in Operation at Jamison Mine No. 9

Date:

1954/10/05

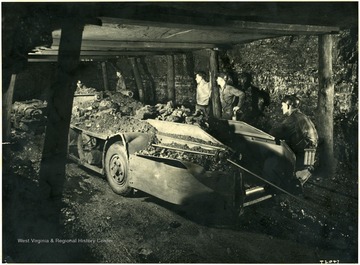

Description:

Two men working on the loading machine.

IDNO:

002151

Title:

Coal on Conveyor

IDNO:

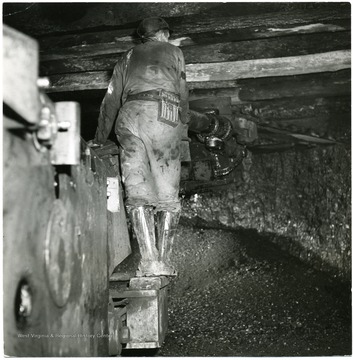

002152

Title:

Miner Operating a Coal Loading Machine

IDNO:

002156

Title:

Making a Cut in Coal Face Prior to 'Shooting Down' Coal

IDNO:

002165

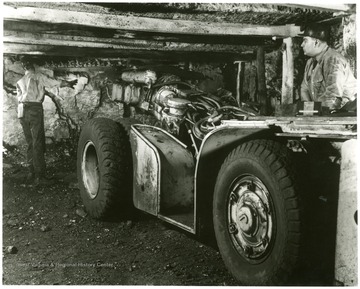

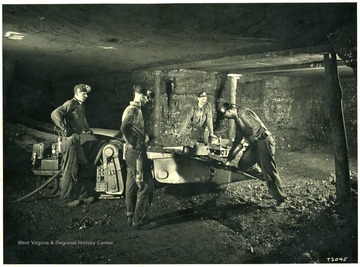

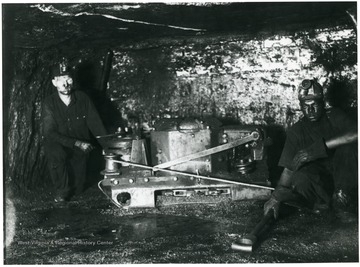

Title:

Miners Operating a Cutting Machine

Description:

Two men working with a rubber tire mounted cutting machine.

IDNO:

002177

Title:

Miner Operates a Coal Cutting Machine Prior to Blasting

IDNO:

002178

Title:

Miners Operating a Cutting Machine

IDNO:

002179

Title:

Miners Operating a Cutting Machine in Pursglove No. 15 Mine

Description:

Two miners cut coal at Pursglove No. 15

IDNO:

002181

Title:

Miners Operating a Cutting Machine at Mine No. 32, Consolidation Coal Company, Owings, W. Va.

Date:

1950/10

Description:

Caption on back reads, 'Making a cut in the coal face is this Mastodon of the machine age - an underground cutter. Rubber tired for mobility, and mounting a 9-foot cutting blade armed with whirring steel bits, it can cut a full 360 degree arc. This and similar machines give America's bituminous coal mines almost unlimited capacity for production.'

IDNO:

002195

Title:

Track Mounted Cutting Machine

Description:

Two miners operate a track mounted coal cutting machine.

IDNO:

002196

Title:

Very Old Track Mounted Cutting Machine

Description:

A gear driven cutting machine stands on the track.

IDNO:

002197

Title:

Breast Type Coal Cutting Machine, Consol Mine No. 26, Watson, W. Va.

Description:

Two miners operate the breast type coal cutting machine.

IDNO:

002200

Title:

Loading Machine in Action at Mine No. 32

Date:

1947/07

Description:

Two men operating a loading machine.

IDNO:

002202

Title:

Joy Manufacturing Company Continuous Mining Machine

IDNO:

002204

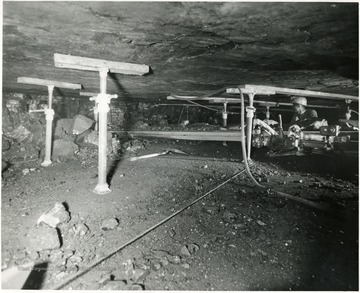

Title:

Miner Cutting Coal in Consol Mine in Kentucky

Description:

Man cutting coal in Consol. Coal Co. Mine in Kentucky. Note the roof supports using jacks.

IDNO:

002206

Title:

Cutting Coal with Cavalier

Description:

Two men cutting coal in the parting.

IDNO:

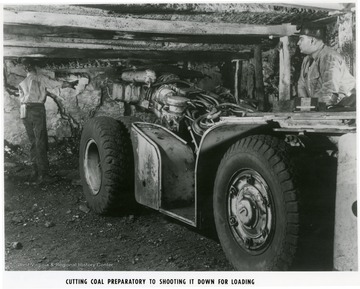

002207

Title:

Cutting Coal Preparatory to Shooting It Down for Loading

IDNO:

002208

Title:

Coal Miner at Work

Description:

A miner operating a coal cutting machine.

IDNO:

002209

Title:

Miner Operating a Small, Track Mounted, Cutting Machine

Description:

Miner on a small, track mounted, cutting machine.

IDNO:

002210

Title:

Miner Operating a Loading Machine

Description:

Miners at work with loading machine and shuttle car.

IDNO:

002211

Title:

Miners Operating a Loading Machine

Date:

undated

Description:

Men at work with loading machine and shuttle car. Probably Joy Machinery.

IDNO:

002218

Title:

Miners Loading Coal Into a Hand Loaded Loading Machine

Date:

1951/04/23

IDNO:

002223

Title:

Miners Roof Bolting at Consol No. 204, Jenkins, Ky.

Description:

Close-up view of roof drill in action. Man in background is tightening bolt with air powered wrench at Consol. No. 204, Jenkins, Ky.

IDNO:

002224

Title:

Cutting Machine in Operation at Mine No. 32

Description:

A coal cutter with nine foot cutting blade at work in Consol. Coal Co. Mine No. 32, Owings, W. Va.

IDNO:

002448

Title:

Machinery at a Coal Mine in Thomas, W. Va.

IDNO:

002455

Title:

Machinery at a Coal Mine in Thomas, W. Va.

IDNO:

002456

Title:

Machinery at a Coal Mine in Thomas, W. Va.

IDNO:

002457

Title:

Machinery at an Unidentified Coal Mine

IDNO:

002458

Title:

Machinery at an Unidentified Coal Mine

IDNO:

002459

Title:

Machinery at an Unidentified Coal Mine

IDNO:

002625

Title:

Interior of a Coal Mine

Description:

Miners and filled coal cars inside a mine.

IDNO:

002626

Title:

Miners and Equipment Inside a Coal Mine

Description:

Miners talking while others run drilling equipment.

IDNO:

002629

Title:

Electric Cable Reel and Joy Shuttle Car with Road Drag at Jamison No. 9 Mine

IDNO:

002657

Title:

Roof Bolting in Pursglove No. 15 Coal Mine

Description:

Miners using a machine to bolt the mine roof.

IDNO:

002675

Title:

Miners Operating a Loading Machine

Description:

Two miners operating a loading machine.

IDNO:

002695

Title:

Cutting Coal by Machine

IDNO:

002696

Title:

Coal Cutting Machine

IDNO:

002700

Title:

Loading Machine Discharges Coal into Shuttle Car

Date:

undated

IDNO:

002701

Title:

Continuous Mining Machine (Middle) and Loading Machine (Bottom)

Date:

1959/04/07

Description:

Mountaineer Coal Company, Division of Consolidation Coal Company.

IDNO:

002704

Title:

Coal Mining, Modern Methods of Production

Description:

1-Mining machine, electrically operated, 2. Electric locomotive and coal car train leaving mine, 3. Shaker screen for sorting coal according to size, 4. Coal powerhouse and tipple.

IDNO:

002705

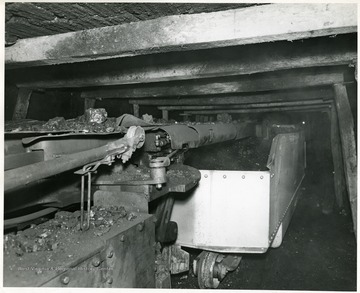

Title:

Shuttle Car Being Loaded by Mechanical Loader

Description:

Rear end of loaded coal car in an underground mine.

IDNO:

002711

Title:

Shuttle Car Being Loaded

Description:

Miner watches as coal loads into a shuttle car.

IDNO:

002713

Title:

Coal Cutting Machine

Description:

Coal cutting machine digs into the coal seam.

IDNO:

002714

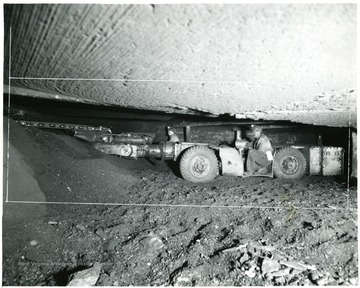

Title:

Continuous Miner in a Tunnel Approximately 4 Feet High

Description:

Continuous mining machine at work.

IDNO:

002715

Title:

Jeffrey Loading Machine Emptying Coal into a New 11-Ton Steel Mine Car at Mine No. 32

Date:

1946/01/19

IDNO:

002720

Title:

Miners Work on a Loading Machine Inside a Mine

IDNO:

002722

Title:

Miner Operating a Joy Cutting Machine

Description:

Pittsburgh Consolidation Coal Company mine.

IDNO:

002726

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002727

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002729

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002730

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002731

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002732

Title:

Room with Mining Machinery and Equipment, Thomas, W. Va.

IDNO:

002733

Title:

Mining Machinery, Thomas, W. Va.

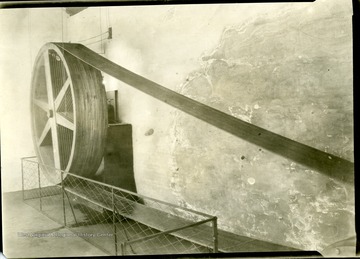

Description:

Close view of a conveyor and engine.

IDNO:

002735

Title:

Mining Machinery, Thomas, W. Va.

Description:

View of a conveyor and engine at a coal mine operation in Thomas, W. Va.

IDNO:

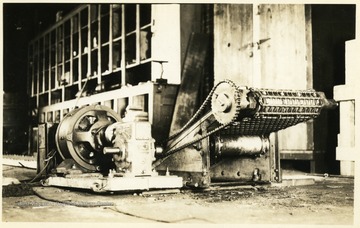

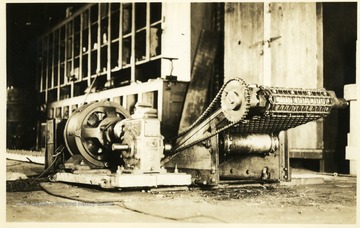

002736

Title:

Mat Conveyor Built in the Shop at Thomas, W. Va.

Date:

1927

IDNO:

002737

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002738

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002739

Title:

Mining Machinery, Thomas, W. Va.

Description:

Close view of a conveyor and engine at a coal mine operation in Thomas, W. Va.

IDNO:

002740

Title:

Mining Machinery, Thomas, W. Va.

Description:

Close view of a conveyor and engine at a coal mine machine shop in Thomas, W. Va.

IDNO:

002741

Title:

Mining Machinery, Thomas, W. Va.

Description:

View of a conveyor in a machine shop at a coal mine in Thomas, W. Va.

IDNO:

002743

Title:

Mining Machinery, Thomas, W. Va.

IDNO:

002744

Title:

Mining Machinery, Thomas, W. Va.

Description:

Close view of a conveyor at a coal mine shop in Thomas, W. Va.

IDNO:

002748

Title:

Mining Equipment at Fairmont Machinery Company

Date:

1918

IDNO:

002752

Title:

Lee Norse CM28E Continuous Miner

Description:

A continuous miner in action.

IDNO:

002753

Title:

Lee Norse CM28E Continuous Miner

Description:

Continuous miner in action.

IDNO:

002759

Title:

Miners Operating a Cutting Machine at Consolidation Coal Company Mine No. 3

IDNO:

002763

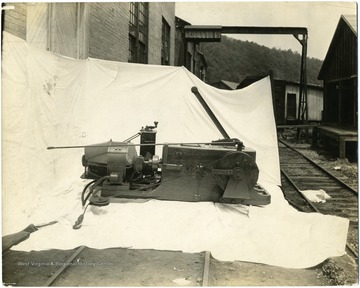

Title:

Mining Equipment at Thomas, W. Va.

Description:

Piece of machinery sitting outside on a white sheet.

IDNO:

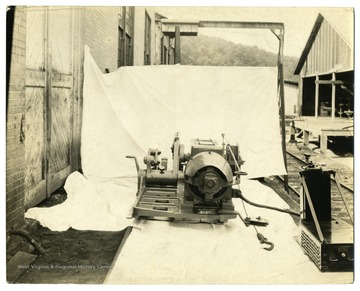

002764

Title:

Mining Equipment at Thomas, W. Va.

Description:

Machinery outside sitting on a white sheet.

IDNO:

002953

Title:

Cutting Machine

Description:

Two miners operate a Sullivan cutting machine.

IDNO:

002970

Title:

Miners at Work in Bethlehem Mine, Barrackville, W. Va.

IDNO:

002973

Title:

Miners Operating a Cutting Machine

Description:

Miners operating a cutting machine.

IDNO:

002976

Title:

Miner Operating a Joy Continuous Mining Machine

IDNO:

002981

Title:

Miners Undercutting Coal with Machine

Date:

undated

Description:

Two miners work with a machine to undercut coal.

IDNO:

002982

Title:

Cutting Machine in Operation at the Pocahontas Exhibition Mine, Pocahontas, Va.

Date:

undated

Description:

Cutting machine in operation at the Pocahontas Exhibition mine, Pocahontas Va. on the Norfolk and Western Railway. 'Permission is granted to reproduce this photograph only on condition that all reproduction shall bear the following credit line: Photograph by Norfolk and Western Railway.'

IDNO:

002983

Title:

Cutting Coal at Pursglove No. 15

Description:

Two miners at Pursglove No. 15 cut coal preparatory to shooting it down for loading.

IDNO:

002984

Title:

Miners with Cutting Machine, Mine 206, Ky.

Date:

undated

Description:

Two miners work with a cutting machine at Mine 206, Kentucky. 'This material is the property of the Consolidation Coal Co. and must be returned promptly to: Advertising Department, Consolidation Coal Company, 30 Rockefeller Plaza, New York, N.Y.

IDNO:

002990

Title:

Cutting Machine in Operation at Mine No. 32

Date:

1947/07

Description:

A very large cutting machine being operated by a miner. 'Credit must be given to William Vandivert, Not to be reproduced without written liscense.

IDNO:

002991

Title:

Mining Operating a Cutting Machine

Description:

'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and place in cutting position as you see it in this picture. The machine consists of an endless chain with 'bits' inserted, which act as cutters. The machine cuts a 'kerf' or hole along the bottom of the coal about 4 inches high and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as 'bug dust.' Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

IDNO:

003003

Title:

Miner Working with Machinery Outside of Mine

Description:

A miner working with machinery on the exterior of a mine.

IDNO:

003011

Title:

Rock Dusting for Safety at Consol Mine No. 207

Description:

Two miners dust the side walls of Mine No. 207 for safety.

IDNO:

003014

Title:

Small Cutting Machine

Description:

Miner using a very small cutting machine.