Limit your search

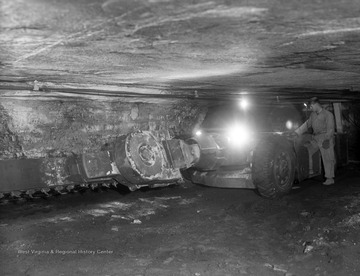

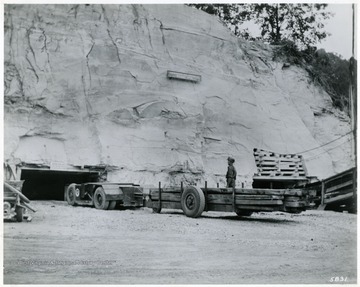

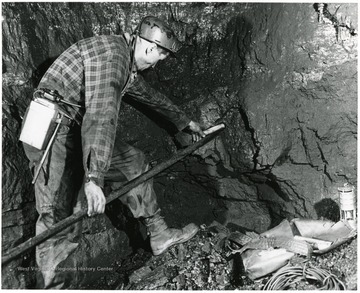

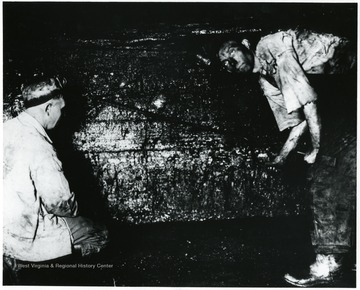

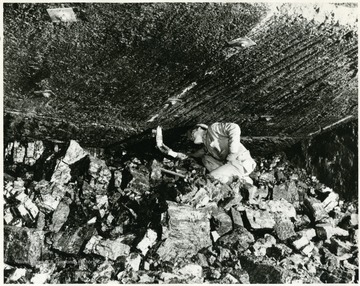

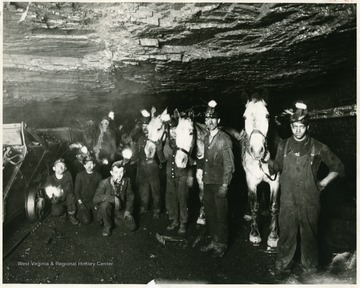

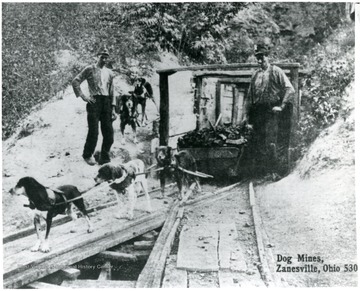

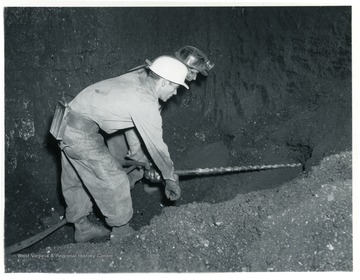

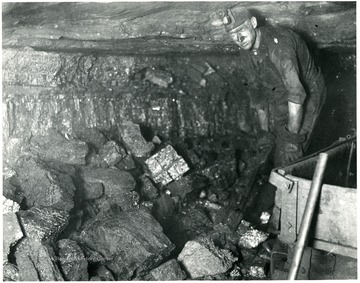

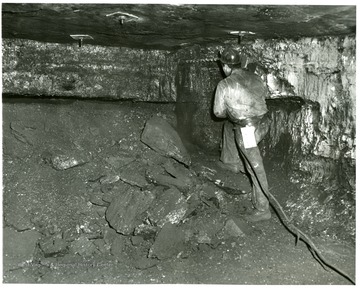

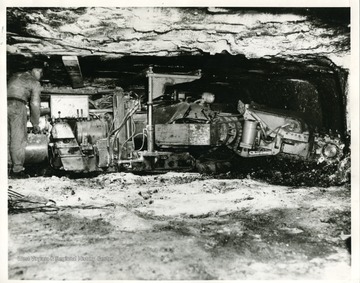

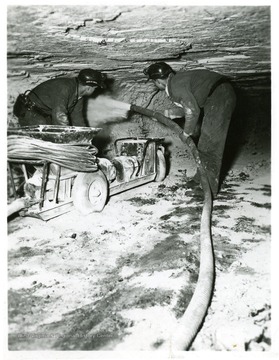

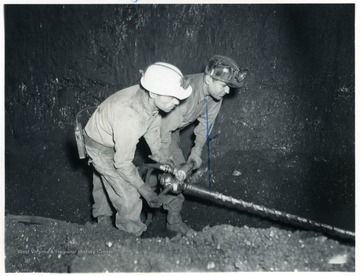

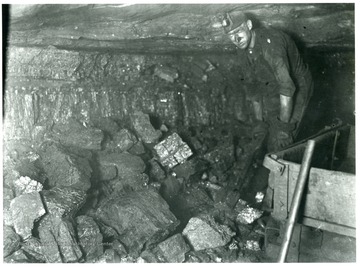

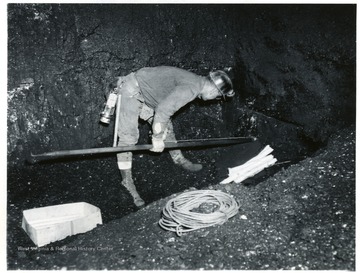

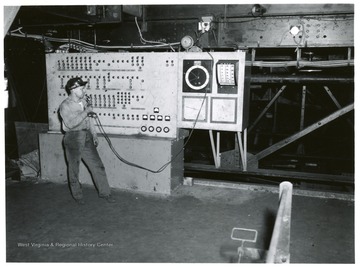

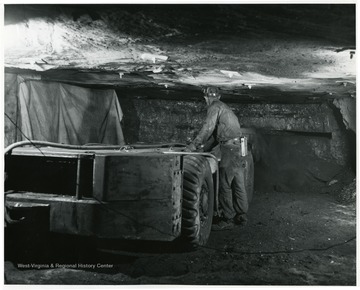

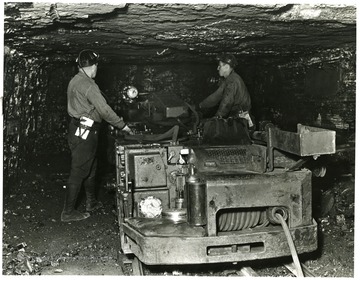

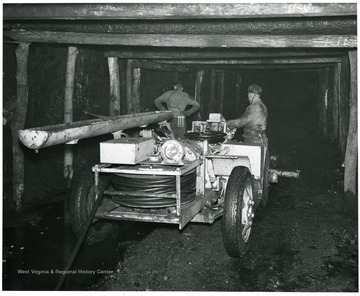

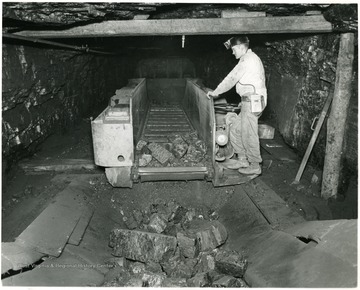

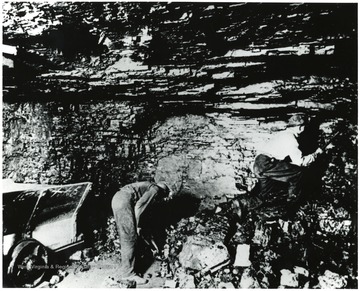

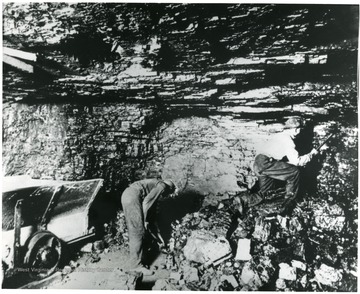

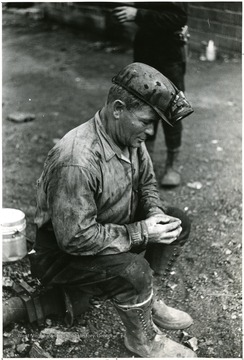

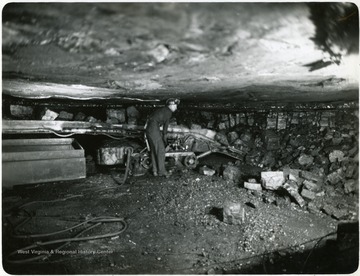

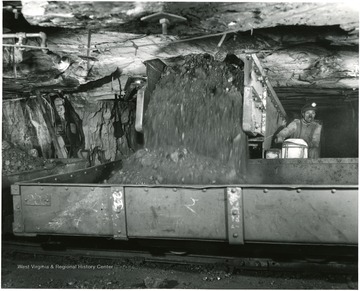

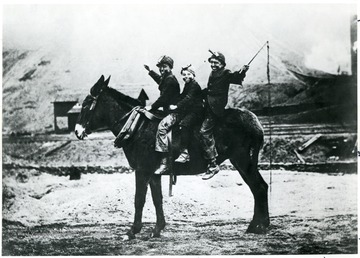

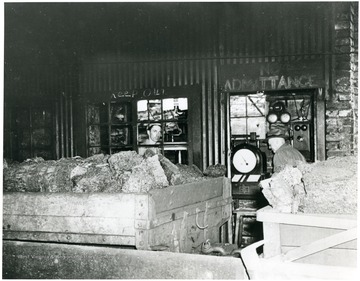

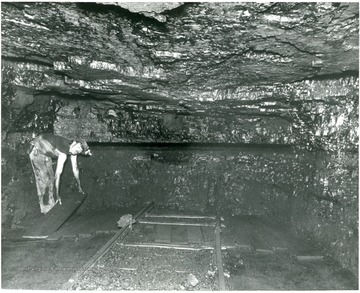

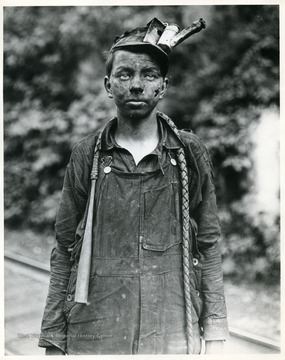

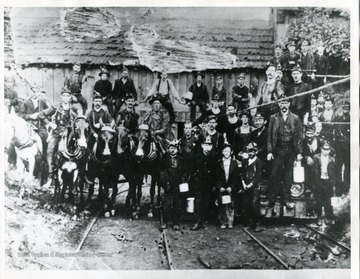

- Coal Mines and Mining--Miners at Work.✖[remove]151

- Coal miners.106

- Coal mines and mining.96

- Coal-mining machinery.37

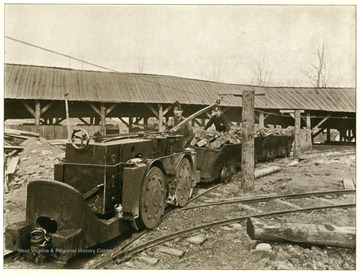

- Mine railroads.13

- Loaders (Machines)12

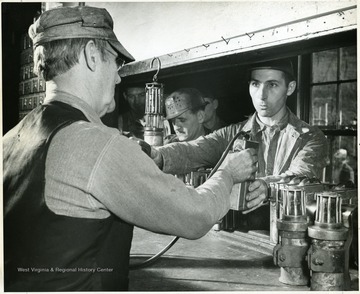

- Mine gases--Measurement.8

- Shuttle cars (Mine haulage)8

- Mine roof bolting.7

- Coal mines and mining--Explosives.6

- Consolidation Coal Company. Jamison Mine no. 9.16

- Consolidation Coal Company. Mine no. 32.5

- Stonega Coke and Coal Company.4

- Consolidation Coal Company. Bishop Mine.3

- Consolidation Coal Company. Pursglove Mine no. 15.3

- Rosedale Coal Company.3

- Bethlehem Mine.2

- Consolidation Coal Company.2

- Consolidation Coal Company. Cavalier Mine no. 206.2

- Consolidation Coal Company. Mine no. 207.2