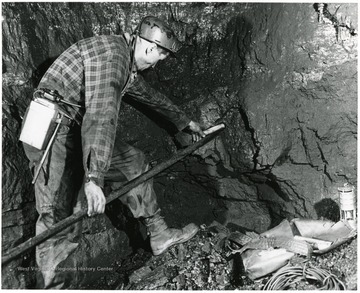

Search Results

IDNO:

003059

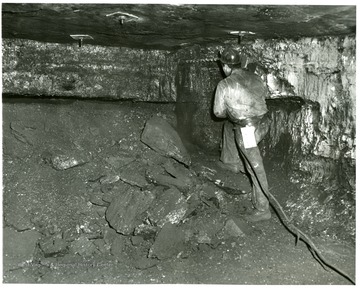

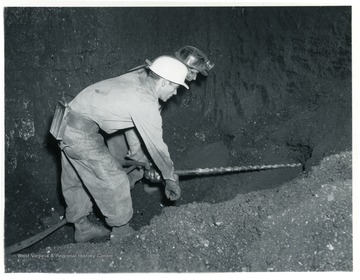

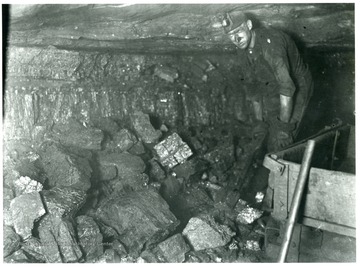

Title:

Drilling Prior to Placing Explosives at Bishop Mine, Pocahontas Fuel Company

Description:

Miner drilling a hole for explosives at the Bishop Mine, Pocahontas Fuel Co.

IDNO:

003080

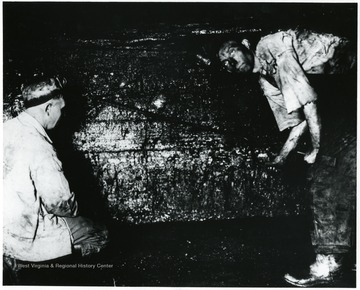

Title:

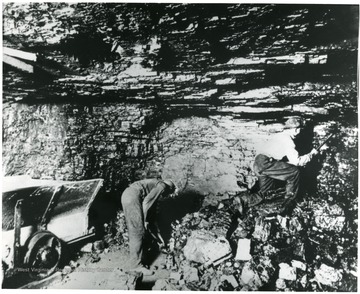

Miners at Work

Description:

Two miners at work drilling into a wall of coal. John Williams, Coal Life Project.

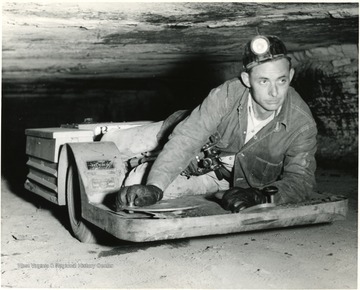

IDNO:

002978

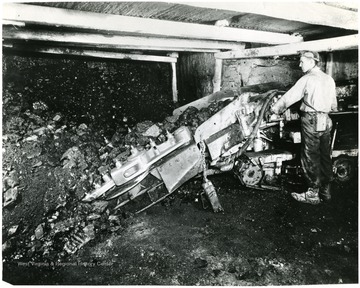

Title:

Joy Loading Machine

Description:

Miner operating a Joy loading machine.

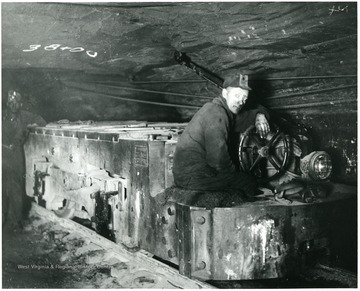

IDNO:

002993

Title:

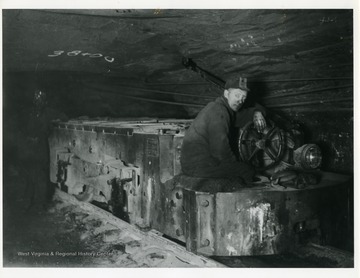

Electric Locomotive Used in Hauling Mine Cars

Description:

Miners on an electric locomotive used in hauling mine cars.

IDNO:

002974

Title:

Loading Machine in Operation

Description:

Miner operating a loading machine.

IDNO:

002972

Title:

Screening Coal, Thomas, W. Va.

Description:

Miners examine coal on conveyor belt.

IDNO:

003005

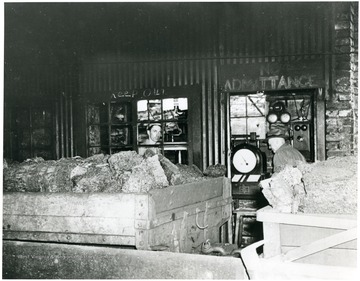

Title:

Scale House at Crane Creek

Description:

Miners and filled coal cars at the Scale House, Crane Creek Mine.

IDNO:

003017

Title:

Miners with Electrical Coal Cutting Machine, Preston County, W. Va.

Description:

Six miners pose by a electrical cutting machine in a mine in Preston County.

IDNO:

003004

Title:

Railroad Car Loading Control Panel

Description:

Miner operating the Railroad car loading control panel.

IDNO:

002992

Title:

Crew Roof Bolting at Bishop Mine

Description:

Three miners putting bolts in the roof at Bishop Mine. Jacks used to hold the roof up while this process was being done.

IDNO:

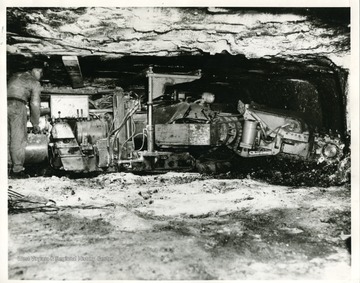

002977

Title:

Modern Joy Loading Machine

Description:

Miner operating a Joy loading machine.

IDNO:

003051

Title:

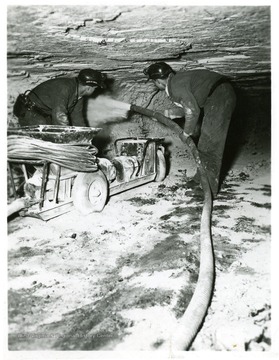

Rock Dusting at Consol. Mine No. 207

Description:

Two miners dust the rocks at Consol Mine No. 207 for safety.

IDNO:

003063

Title:

Drilling Prior to 'Setting' Explosives at Jamison No. 9

Description:

Miner drilling holes for explosives at Jamison No. 9.

IDNO:

003003

Title:

Miner Working with Machinery Outside of Mine

Description:

A miner working with machinery on the exterior of a mine.

IDNO:

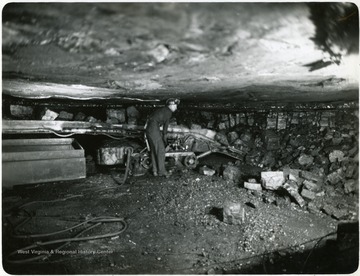

003010

Title:

Mechanical Loader at Cinderella Mine, Mingo Co., W. Va.

Description:

Miner standing over a mechanical loader at the Winifrede Seam, Sycamore Coal Co. Cinderella Mine, Mingo Co., W. Va.

IDNO:

003021

Title:

Mining Operating a Cutting Machine

Description:

Two miners work with a mining machine. 'Compliments of Jeffrey Manufacturing Co.' John Williams, Coal Life Project.

IDNO:

002953

Title:

Cutting Machine

Description:

Two miners operate a Sullivan cutting machine.

IDNO:

003035

Title:

Modern Coal Cutting Machine in Operation at Bishop Mine

Description:

A modern coal cutting machine in operation at Bishop Mine.

IDNO:

003077

Title:

Miner Placing a Charge

Description:

'Charge being placed in the hole; notice preparatory cut in the center.'

IDNO:

003053

Title:

Sewall Coal Seam Worked by the New River Coal Company

Description:

'All White Oak mines work the same seam of coal, viz: Sewall...The face of one of the working places or rooms is shown in this picture. The coal averages about 48 to 50 inches in thickness. This working place is now ready to be cut by the undercutting machine, so it can be shot down by the miner and loaded into the cars for transportations to the tipple. The white line on the roof in this picture is the center line of the room set by the engineers to guide the men operating the mining machine in driving the room straight.'

IDNO:

003025

Title:

Cutting Coal

Description:

Miner using machine to cut coal.

IDNO:

003011

Title:

Rock Dusting for Safety at Consol Mine No. 207

Description:

Two miners dust the side walls of Mine No. 207 for safety.

IDNO:

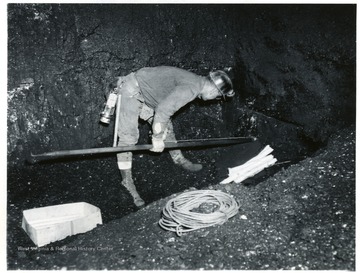

002946

Title:

Miner Roof Bolting

Description:

Miner putting bolts into the roof of a mine for support.

IDNO:

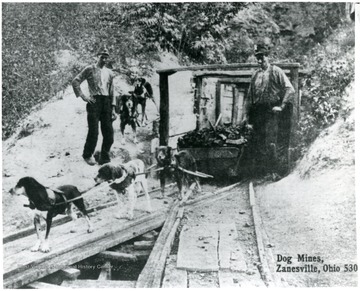

003071

Title:

Dog Mines, Zanesville, Ohio

Description:

Two miners watching dogs haul loads of coal.

IDNO:

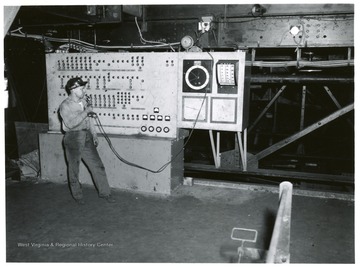

003036

Title:

Control Board at Jamison No. 9

Description:

Miner speaking in microphone at control board at Jamison No. 9.

IDNO:

003073

Title:

Miners and Their Horses

Description:

Group portrait of miners and horses inside a mine. 'Dr. Parkinson said a copy of this picture appeared in Natural Geographic's Pictorical Study of Appalachia.'

IDNO:

003072

Title:

Dog Mines, Zanesville, Ohio

Description:

Two miners watching dogs haul loads of coal.

IDNO:

003056

Title:

Continuous Mining Machine, Helper and Crew

Description:

'Machine, helper and crew. 350 tons a day, per 8 hour shift.'

IDNO:

003081

Title:

Miner Placing a Charge

Description:

A miner at work placing a charge.

IDNO:

003039

Title:

Control Board at Jamison No. 9

Description:

Miner at control board at Jamison No. 9.

IDNO:

003029

Title:

Cutting Machine Prior to Shooting Down Coal at Pursglove No. 15

Description:

Miners work with a cutting machine prior to 'shooting down' coal at Pursglove No. 15.

IDNO:

003015

Title:

Miners at Work in Mine Interior

Description:

Two miners work on a seam, one with a pick, the other with a shovel.

IDNO:

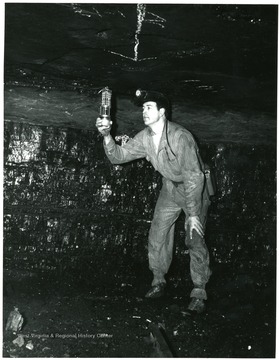

002960

Title:

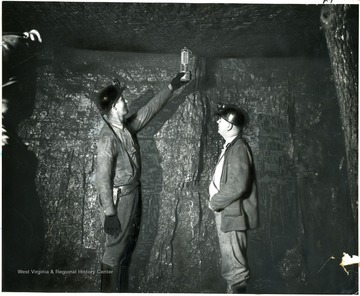

Testing for Gas

Description:

Two miners test for gas in mine. Hamilton Wright Organization Inc. 80 Rockefeller Plaza, New York City, 'Newspaper Feature News' This photograph released to you GRATIS for editorial use only. Do not use for advertising purpose without written permission.

IDNO:

002983

Title:

Cutting Coal at Pursglove No. 15

Description:

Two miners at Pursglove No. 15 cut coal preparatory to shooting it down for loading.

IDNO:

002975

Title:

Joy Loading Machine in Action

Description:

Miner operating a Joy Loading Machine. '180 tons a day.'

IDNO:

003075

Title:

Dog Mines, Zanesville, Ohio

Description:

Miners and horses and dogs used to haul cart loads full of coal.

IDNO:

003040

Title:

Setting Explosives at Jamison No. 9

Description:

Miner setting charges at Jamison No. 9.

IDNO:

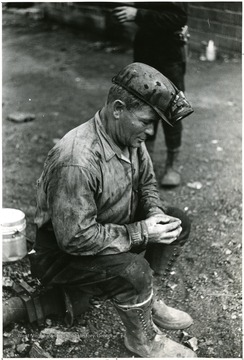

003013

Title:

Miner Taking a Break

Description:

Unknown miner sitting down outside of the mine. 'Please credit Farm Security Administration for Photo.

IDNO:

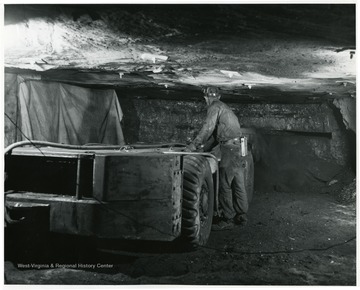

003069

Title:

Electric Shuttle Car

Description:

A miner operating an electric shuttle car filled with coal.

IDNO:

003012

Title:

Miners Working at Coke Ovens

Description:

Miner works with coke ovens while a loading machine fills railroad cars.

IDNO:

003045

Title:

Jamison No. 9 Mine Locomotive

Description:

Miners ride in a locomotive at Jamison No. 9.

IDNO:

003046

Title:

Jeffrey 290 cutting trench for 2200 volt line at Jamison No. 9

Description:

Jeffrey 290 cutting trench for 2200 volt line at Jamison No. 9. Stonega Coke and Coal.

IDNO:

003054

Title:

Drilling Machine at Jamison No. 9

Description:

Miner with drilling machine at Jamison No. 9.

IDNO:

003041

Title:

Miner Loading Coarse Lumpy Coal

Description:

'Coarse Lumpy Coal: This very coarse lumpy mine run coal is the result of proper shooting. The miner is paid on a tonnage basis for loading this coal into mine cars. He is required to watch his coal carefully as he loads it and she that no impurities become mixed with the coal.'

IDNO:

003079

Title:

Miner Testing for Gas

IDNO:

002954

Title:

Testing for Gas

Description:

Miner tests for gas in mine.

IDNO:

003038

Title:

Wetting Coal to Retard Coal Dust

Description:

Miner unloading coal into car while it is being sprayed to retard dust.

IDNO:

002980

Title:

Miner Operating an Electric Car, Consolidation Coal Company, Ky.

Description:

Man riding an electric car.

IDNO:

002976

Title:

Miner Operating a Joy Continuous Mining Machine

IDNO:

002986

Title:

Miner on Electric Locomotive

Description:

Two miners next to an electric locomotive.

IDNO:

002996

Title:

Miner Operating an Electric Locomotive

Description:

'An Electric Locomotive: Good dependable motive power is just as necessary in a coal mine as on a railroad. This picture shows on of White Oak's ten ton electric locomotives used to haul loads and distrubute empties in our mines. A crew consists of a motorman and brakeman, or trip rider, who pull loads from the working places to convenient sidings where they are picked up by main line locomotives, who haul to the tipple or shaft bottom. A large producing mine uses fifteen and twenty locomotives and five hundred mine cars in maintaining production.'

IDNO:

002999

Title:

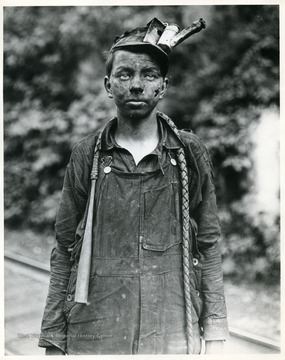

Young Driver in Mine, Brown Mine, Brown, W. Va.

Description:

Lewis Hine, photographer took this picture of a young driver in Brown Mine, Brown, W. Va.

IDNO:

033241

Title:

Miner Operating a Coal Cutting Machine

IDNO:

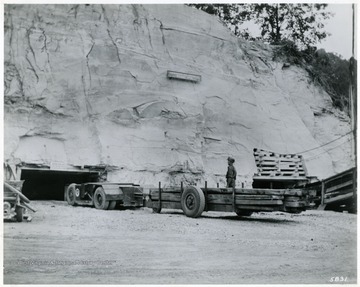

033523

Title:

Transporting Lumber for Shoring in a Coal Mine

IDNO:

033525

Title:

Transporting Lumber for Shoring in Wright Mine, K.Y.

Description:

The sign on the mine says, Consolidation Coal Company KY Wright Mine'