Limit your search

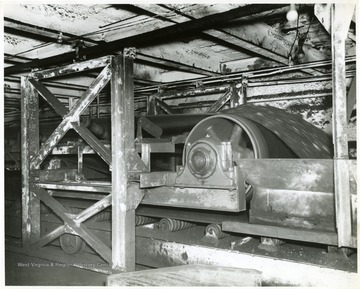

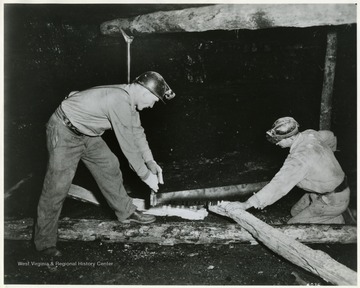

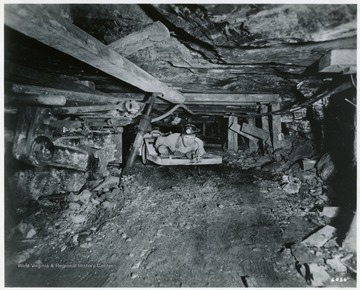

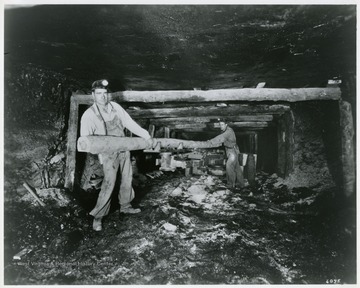

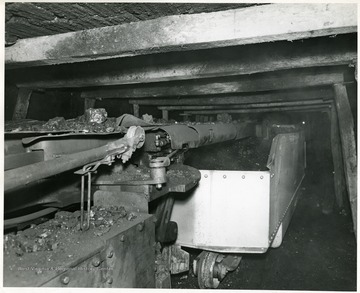

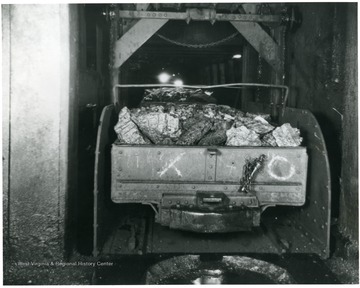

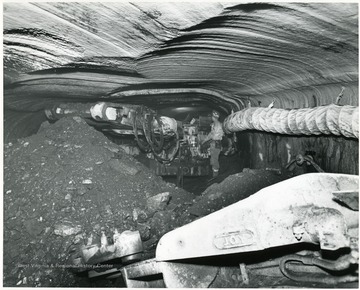

- Coal Mines and Mining--Mine Interiors--Machinery.✖[remove]62

- Coal mines and mining.✖[remove]62

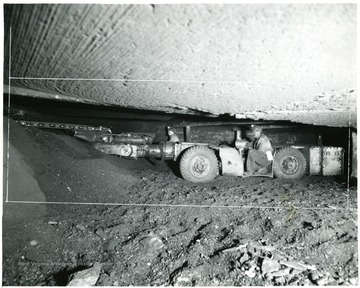

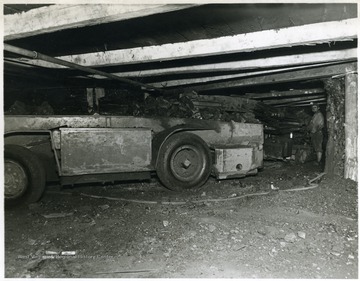

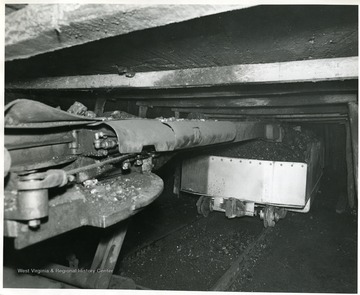

- Coal-mining machinery.29

- Coal miners.22

- Shuttle cars (Mine haulage)10

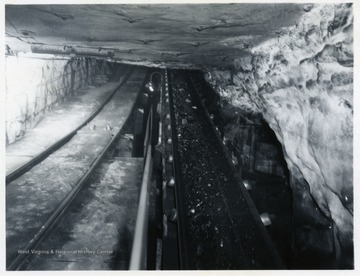

- Conveying machinery.7

- Mine timbering.7

- Coal-handling machinery.5

- Mine railroads--Cars.3

- Coal--Transportation.2

- print62

- West Virginia History OnView✖[remove]62