Search Constraints

You searched for:

Medium

print

Remove constraint Medium: print

Topical Subjects

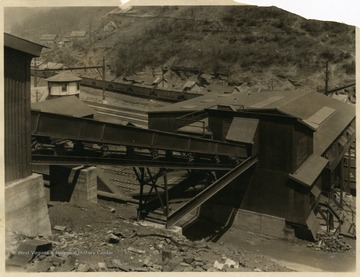

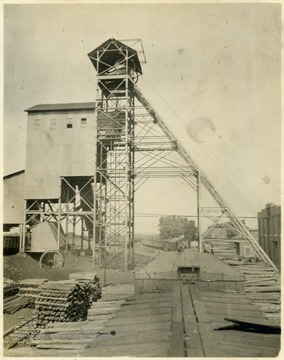

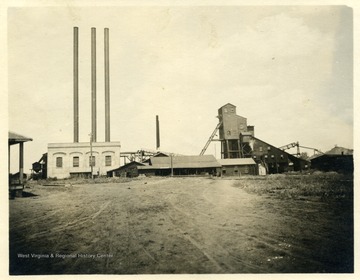

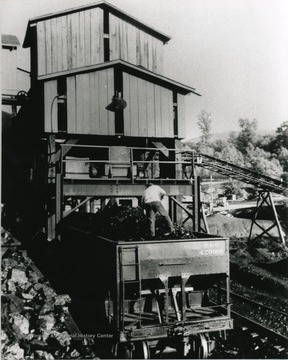

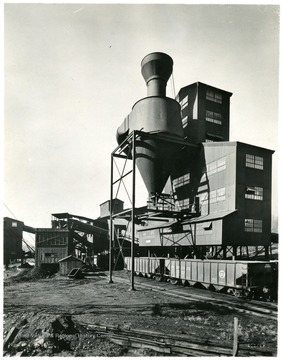

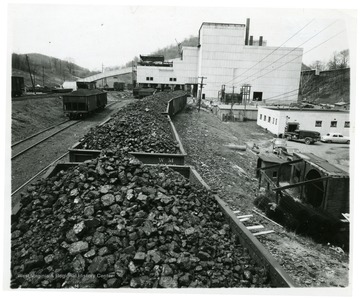

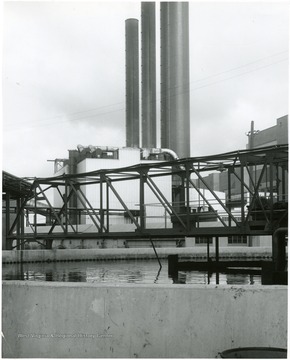

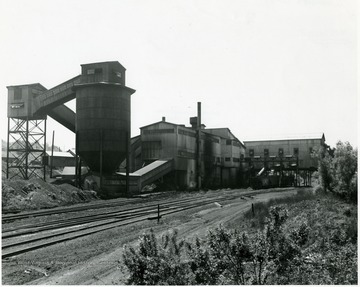

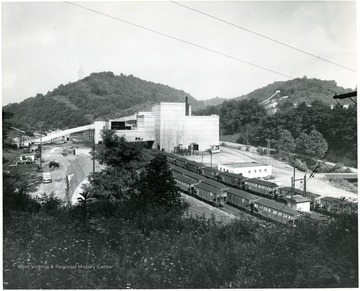

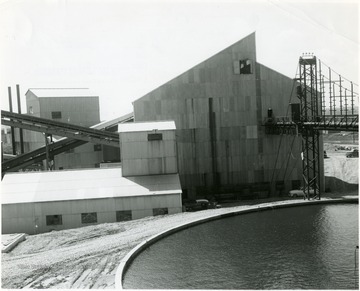

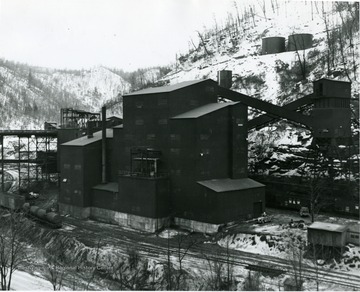

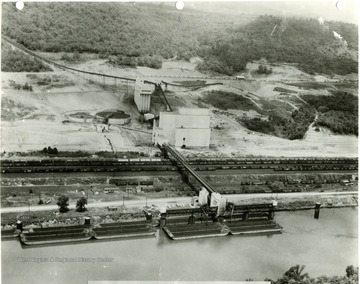

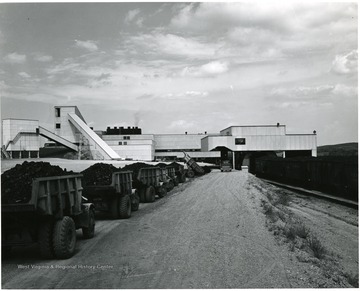

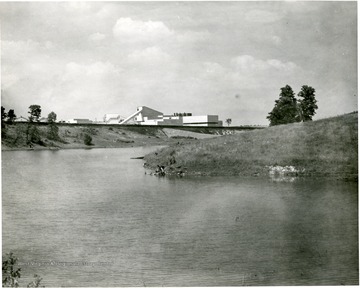

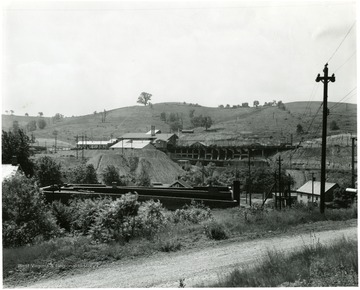

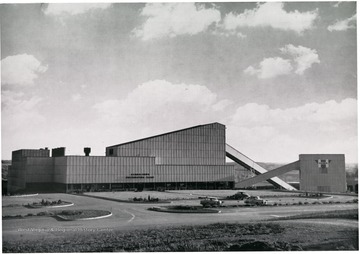

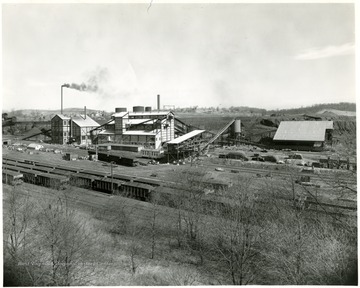

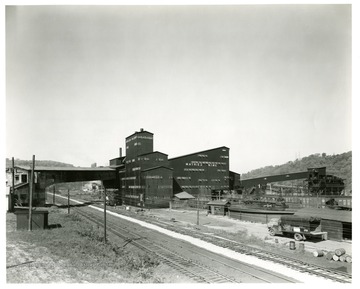

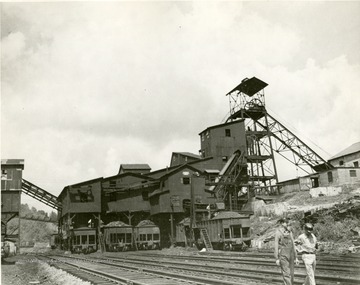

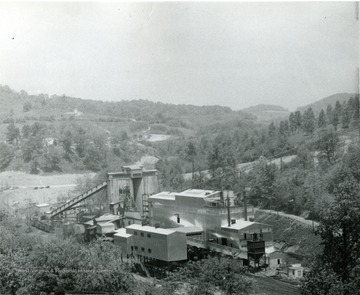

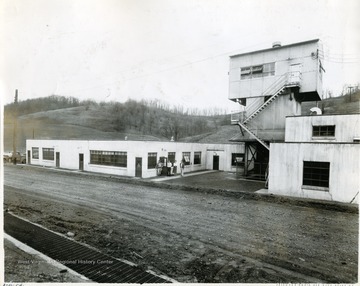

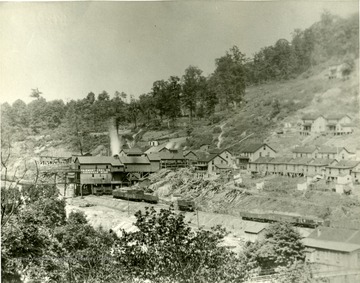

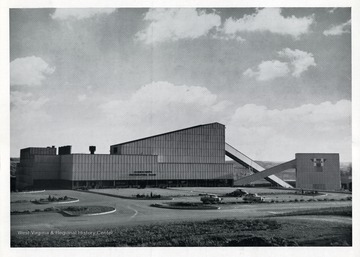

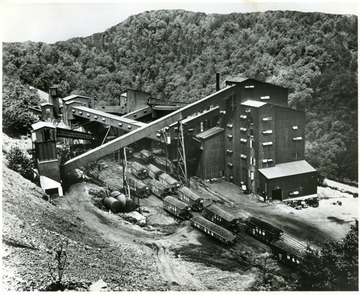

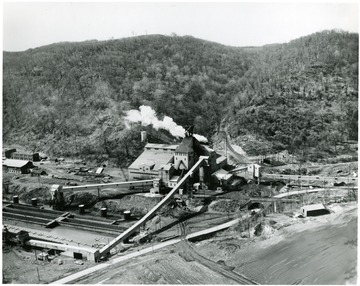

Coal preparation plants.

Remove constraint Topical Subjects: Coal preparation plants.

« Previous |

1 - 96 of 141

|

Next »