Limit your search

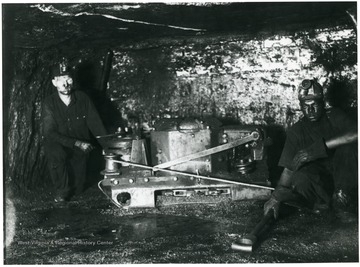

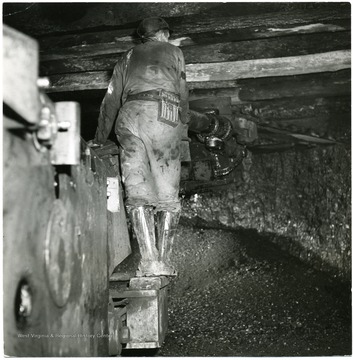

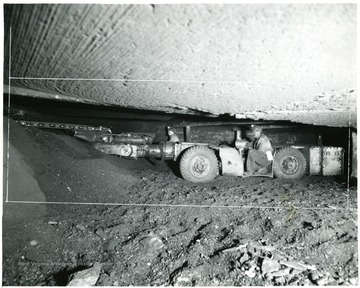

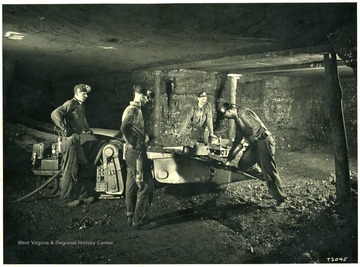

- Coal miners.✖[remove]53

- Coal mines and mining.✖[remove]53

- Coal-mining machinery.✖[remove]53

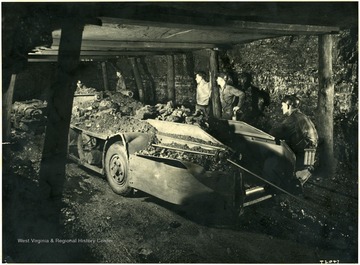

- Coal Mines and Mining--Miners at Work.26

- Coal Mines and Mining--Mine Interiors--Machinery.10

- Coal Mines and Mining--Pocahontas Operators Association.7

- Coal Mines and Mining--Consolidation Coal Company.5

- Coal Mines and Mining--Mine Interiors.4

- Loaders (Machines)4

- Boring.1

- Consolidation Coal Company. Jamison Mine no. 9.6

- Consolidation Coal Company. Mine no. 32.3

- Stonega Coke and Coal Company.3

- Consolidation Coal Company. Pursglove Mine no. 15.2

- Price Hill Colliery Company.2

- Consolidation Coal Company.1

- Consolidation Coal Company. Bishop Mine.1

- Consolidation Coal Company. Mine no. 3.1

- Pocahontas Mine.1

- print✖[remove]53

- West Virginia History OnView✖[remove]53