Search Constraints

« Previous |

1 - 48 of 96

|

Next »

Search Results

IDNO:

003050

Title:

Continuous Mining Machine

Date:

undated

Description:

Miner running a continuous mining machine.

IDNO:

002981

Title:

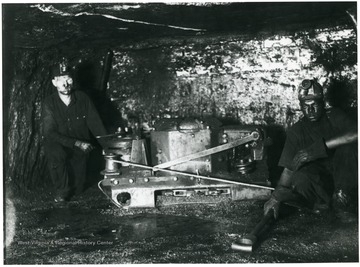

Miners Undercutting Coal with Machine

Date:

undated

Description:

Two miners work with a machine to undercut coal.

IDNO:

003060

Title:

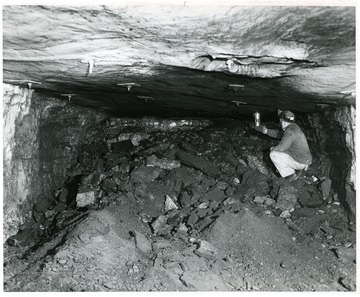

Drilling Prior to Setting Explosives

Date:

ca. 1940-1950

Description:

Miners drill two or more holes into coal to place the explosive charges.

IDNO:

003008

Title:

Loading Machine at MacAlpin Coal Company

Date:

ca. 1920-1930

Description:

Miner operating a loading machine outside of a mine.

IDNO:

003061

Title:

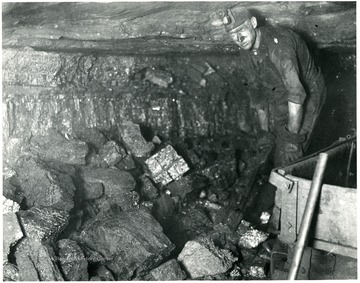

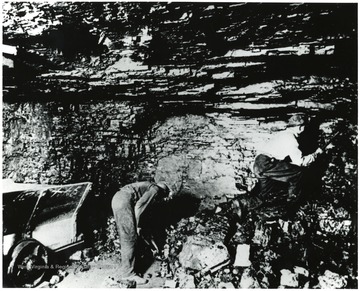

Miner Prepares to Load Coal After Shooting

Date:

ca. 1920

Description:

'This very coarse lumpy mine run coal is the result of proper shooting. The miner is paid on a tonnage basis for loading this coal into mine cars. He is required to watch his coal carefully as he loads it and see that no impurities become mixed with the coal.'

IDNO:

003057

Title:

Dogs in Harness, Ohio Coal Mine

Date:

ca. 1890

Description:

Two dogs harnessed to coal carts. About 1890, Ohio Coal Mine. This photograph is the property of Pittsburgh Consolidation Coal Co.

IDNO:

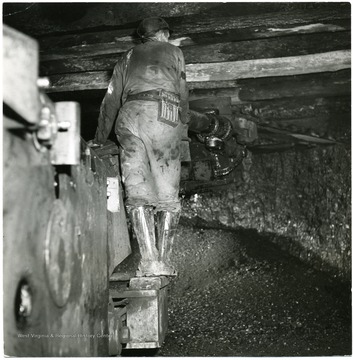

003001

Title:

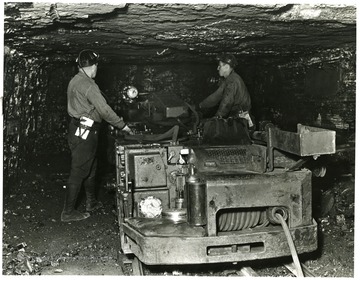

Miners Working with Loading Machine

Date:

1959/04/07

Description:

Miners at work. 'Mountaineer Coal Co., Division of Consolidation Coal Co.'

IDNO:

003032

Title:

Cutting Machine at Jamison No. 9

Date:

1954/10/05

Description:

Miner works with cutting machine at Jamison No. 9 mine.

IDNO:

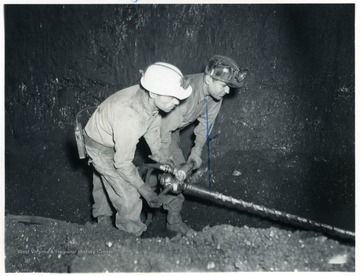

003062

Title:

Miners Operating a Cutting Machine at Pursglove No. 15

Date:

1954/01/13

Description:

Two miners work with a cutting machine at Pursglove No. 15.

IDNO:

003065

Title:

Miners at Work in an Itmann Coal Company Mine

Date:

1953/07

Description:

Two miners working to support the roof in the Itmann Coal Co. mine.

IDNO:

003191

Title:

Cutting Machine in Operation

Date:

1947/07

Description:

Two miners operate a cutting machine. 'Credit must be given to Willaim Vandivert, 21 East Tenth St., New York 3, N.Y., Not to be reproduced without written liscense.'

IDNO:

002990

Title:

Cutting Machine in Operation at Mine No. 32

Date:

1947/07

Description:

A very large cutting machine being operated by a miner. 'Credit must be given to William Vandivert, Not to be reproduced without written liscense.

IDNO:

003076

Title:

Mining Coal

Date:

1947/07

Description:

Three miners hard at work as coal comes down a conveyor. Copyright Photo by William Vandivert, 21 East Tenth Street, New York 3, N. Y.

IDNO:

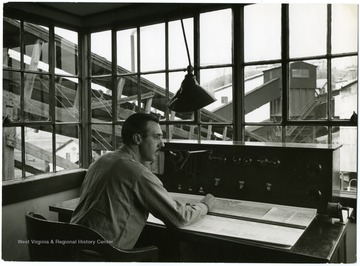

002995

Title:

Dispatcher at Mine No. 32

Date:

1947

Description:

Dispatcher in office outside of mine. 'Credit must be given to William Vandivert, and picture is not to be reproduced without written license.'

IDNO:

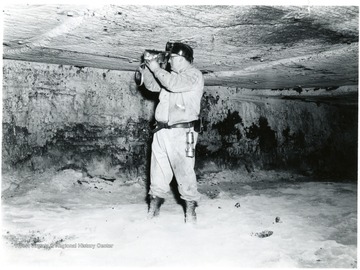

002945

Title:

Miner Roof Bolting

Description:

Miner putting bolts into the roof of a mine for support.

IDNO:

003047

Title:

Miner Operating a Loading Machine at Jamison No. 9

Description:

Miner using a 11 BU loading machine at Jamison No. 9. Stonega Coke and Coal.

IDNO:

002944

Title:

Miner Roof Bolting

Description:

Miner putting bolts into the roof of a mine for support.

IDNO:

002991

Title:

Mining Operating a Cutting Machine

Description:

'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and place in cutting position as you see it in this picture. The machine consists of an endless chain with 'bits' inserted, which act as cutters. The machine cuts a 'kerf' or hole along the bottom of the coal about 4 inches high and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as 'bug dust.' Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

IDNO:

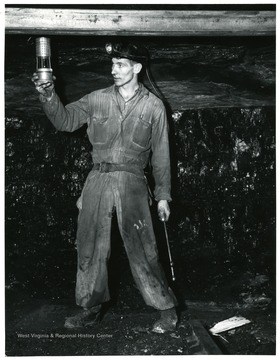

002958

Title:

Miners Testing for Gas in a Coal MIne

IDNO:

003018

Title:

Miners at Work

Description:

Two miners work on filling up a coal tram car. John Williams, Coal Life Project.

IDNO:

002943

Title:

Battery Powered 'Self Unloader' Shuttle Car Hauling Coal to Loading Station

Description:

A miner is driving a battery powered shuttle car that is self unloading to the loading station.

IDNO:

003027

Title:

Continuous Mining Machine at Brock No. 4 Mine

Description:

Continuous mining machine on arrival at Brock No. 4 Mine before taken inside mine.

IDNO:

002973

Title:

Miners Operating a Cutting Machine

Description:

Miners operating a cutting machine.

IDNO:

002951

Title:

Miner Placing Boards on the Floor of Cavalier Mine No. 206

Description:

Miner placing boards in Cavalier Mine No. 206.

IDNO:

003019

Title:

Miner Working on Machinery

Description:

A miner works on a piece of machinery on the interior of the mine. John Williams, Coal Life Project.

IDNO:

003037

Title:

Shuttle Car Being Loaded

Description:

Miner waiting for shuttle car to be loaded.

IDNO:

002994

Title:

Jamison No. 9 Mine Locomotive

Description:

Miners stand next to a large locomotive at Jamison No. 9.

IDNO:

002985

Title:

Miners Roof Bolting

Description:

Two miners work on putting in roof bolts in the Pittsburgh Seam. Timber jack used to hold the roof while bolting.

IDNO:

002949

Title:

Testing for Gas After Shooting at Bishop's Mine

Description:

Miner tests for gas after shooting of coal in Bishop's Mine, Poca Fuel Co.?

IDNO:

003066

Title:

Miner Operating a Cutting Machine, Price Hill Colliery Company

Description:

A miner is operating a cutting machine at the Price Hill Colliery Co. mine

IDNO:

003033

Title:

Track Mounted Cutting Machine at Consolidation Coal Mine No. 32.

Description:

Miners using a cutting machine at Mine 32, Consolidation Coal Co.

IDNO:

003042

Title:

Drilling Prior to Setting Explosives

Description:

Two miners drill before placing charges.

IDNO:

003020

Title:

Loading Machine in Action

Description:

Miner working with a loading machine. 'Compliments of Joy Manufacturing Co.'

IDNO:

002956

Title:

Testing for Gas

Description:

Miner tests for gas in mine.

IDNO:

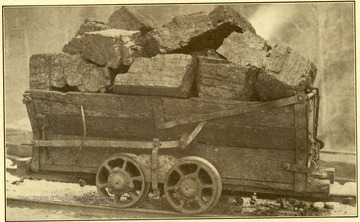

002989

Title:

Coalburg Coal at Mine of Kelley Creek Colliery Company

Description:

Car filled with coal. 'Geological Survey'

IDNO:

003030

Title:

Shuttle Car Unloading into an Elevator

Description:

Miner works at unloading a shuttle car into an elevator.

IDNO:

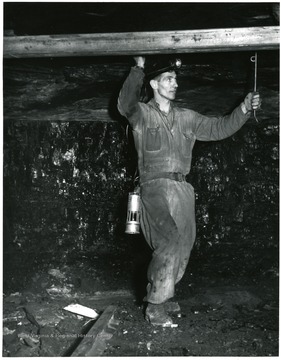

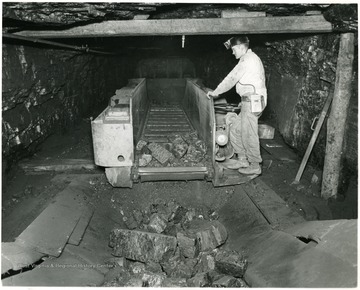

002948

Title:

Coal Shot Down and Ready for Loading

Description:

Miner stands on pile of coal ready to be loaded and sent out of mine.

IDNO:

003022

Title:

Miner Operating Cuttting Machine

IDNO:

002964

Title:

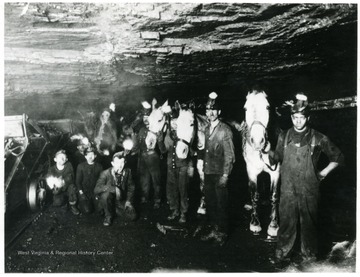

Miners and Horse Drawn Cart

Description:

Group portrait of miners standing with horses in a mine.

IDNO:

003049

Title:

Miner Operating a Cutting Machine

Description:

'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and placed in cutting position as you see in this picture. The machine consists of an endless chain with bits inserted, which act as cutters. The machine cuts a kerf or hole along the bottom of the coal about 4 feet and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as bug dust. Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

IDNO:

003044

Title:

Control Panel at Jamison No. 9

Description:

Miner works at the control panel at Jamison No. 9.

IDNO:

003043

Title:

Joy Roof Bolt Drill at Jamison No. 9

Description:

Two miners work with a Joy roof bolt drill at Jamison No. 9.

IDNO:

003068

Title:

Miners Operating a Cutting Machine

Description:

'A very small cutting machine or a v.m. drilling machine. Probably a cutting machine'

IDNO:

002979

Title:

Joy Manufacturing Company Continuous Mining Machine

Description:

Miner operating a Joy continuous mining machine.

IDNO:

002961

Title:

Testing for Gas at Jamison No. 9 Mine

Description:

Man tests for gas at the Jamison No. 9 Mine.

IDNO:

003014

Title:

Small Cutting Machine

Description:

Miner using a very small cutting machine.

IDNO:

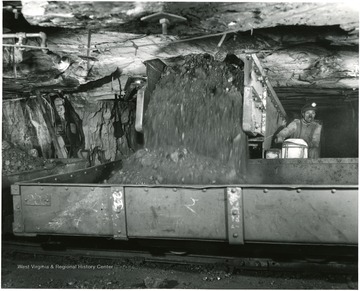

003007

Title:

Shuttle Car Discharges its Load into Mine Cars

Description:

A miner watches as coal is loaded into mine cars from a shuttle car.

IDNO:

003067

Title:

Slate Intrusion at No. 63

Description:

Chalk markings designate slate intrusion in No. 63.