Limit your search

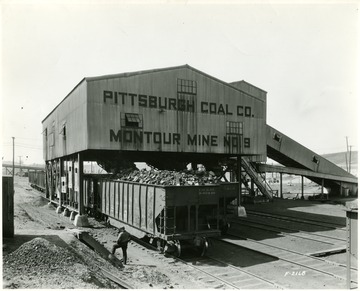

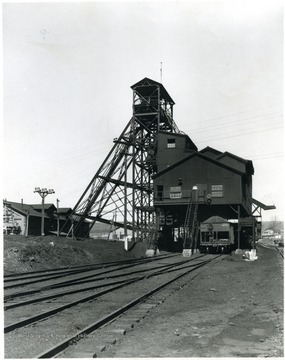

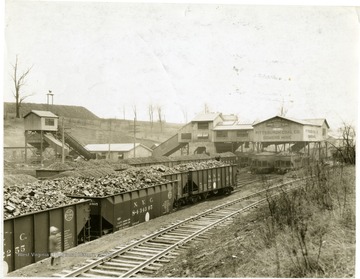

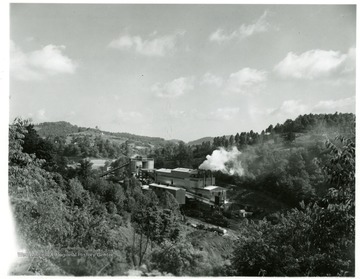

- Coal mines and mining.217

- Coal miners.118

- Coal Mines and Mining--Consolidation Coal Company.100

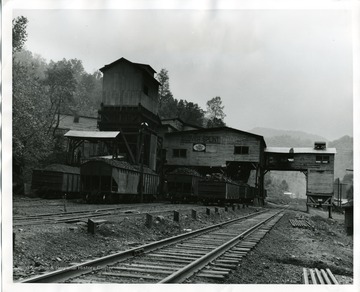

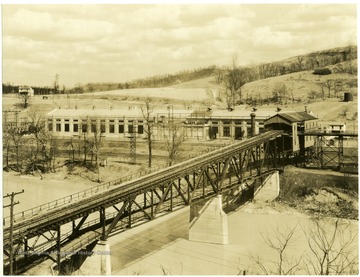

- Coal Mines and Mining--Preparation Plant Exteriors.94

- Coal preparation plants.89

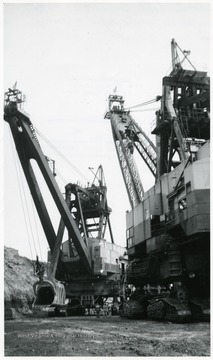

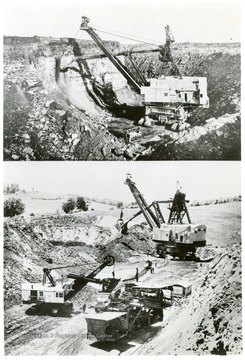

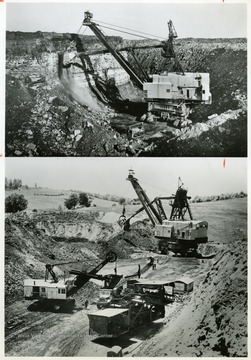

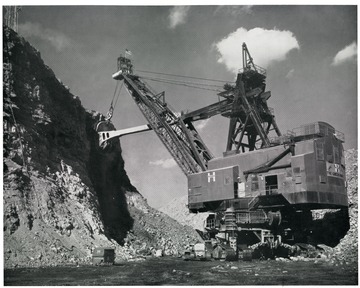

- Power shovels.79

- Coal Mines and Mining--Miners at Work.77

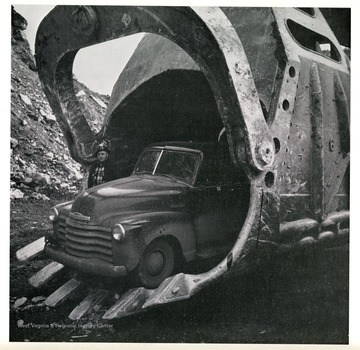

- Coal-mining machinery.76

- Coal Mines and Mining--Portraits--Group.73

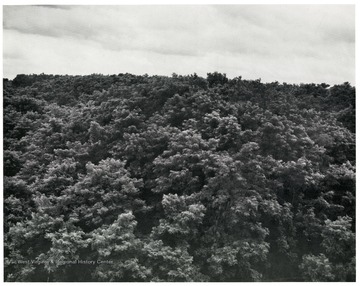

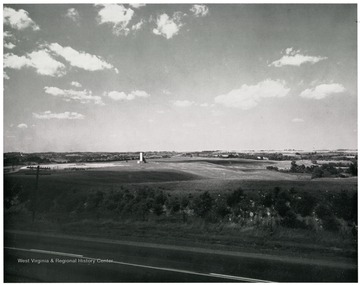

- Strip mining.61

- Hanna Coal Company.89

- Consolidation Coal Company. Jamison Mine no. 9.68

- Consolidation Coal Company.66

- Mountaineer (Power shovel)35

- Consolidation Coal Company. Mine no. 32.16

- Hanna Coal Company. Georgetown Preparation Plant.16

- Consolidation Coal Company. Williams Mine.13

- Consolidation Coal Company. Mathies Mine.12

- Consolidation Coal Company. Ireland Mine.11

- Consolidation Coal Company. Mine no. 32 (Owings, W. Va.)8

- Consolidation Coal Company✖[remove]756

- print✖[remove]756

- West Virginia History OnView✖[remove]756