Search Results

- IDNO:

- 002989

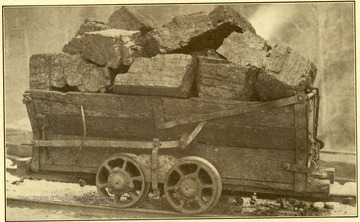

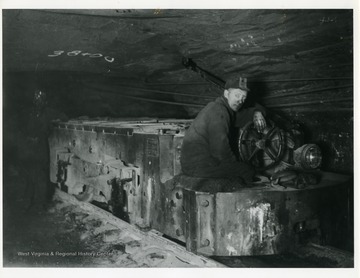

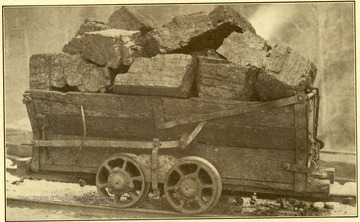

- Title:

- Coalburg Coal at Mine of Kelley Creek Colliery Company

- Description:

- Car filled with coal. 'Geological Survey'

- IDNO:

- 002990

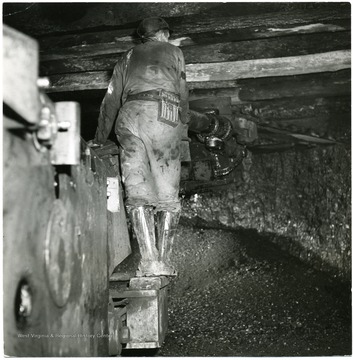

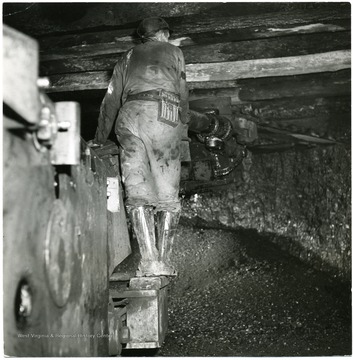

- Title:

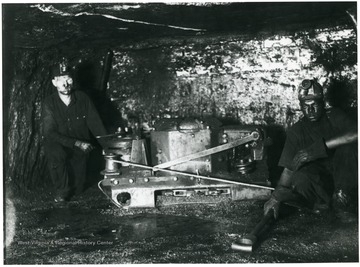

- Cutting Machine in Operation at Mine No. 32

- Date:

- 1947/07

- Description:

- A very large cutting machine being operated by a miner. 'Credit must be given to William Vandivert, Not to be reproduced without written liscense.

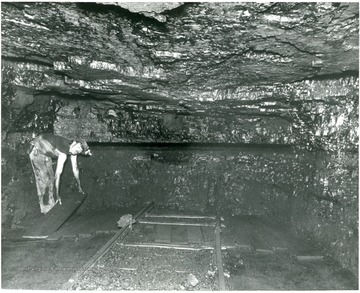

- IDNO:

- 002991

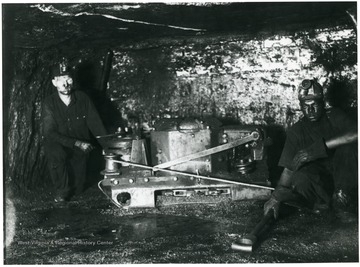

- Title:

- Mining Operating a Cutting Machine

- Description:

- 'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and place in cutting position as you see it in this picture. The machine consists of an endless chain with 'bits' inserted, which act as cutters. The machine cuts a 'kerf' or hole along the bottom of the coal about 4 inches high and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as 'bug dust.' Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

- IDNO:

- 002992

- Title:

- Crew Roof Bolting at Bishop Mine

- Description:

- Three miners putting bolts in the roof at Bishop Mine. Jacks used to hold the roof up while this process was being done.

- IDNO:

- 002993

- Title:

- Electric Locomotive Used in Hauling Mine Cars

- Description:

- Miners on an electric locomotive used in hauling mine cars.

- IDNO:

- 002994

- Title:

- Jamison No. 9 Mine Locomotive

- Description:

- Miners stand next to a large locomotive at Jamison No. 9.

- IDNO:

- 002995

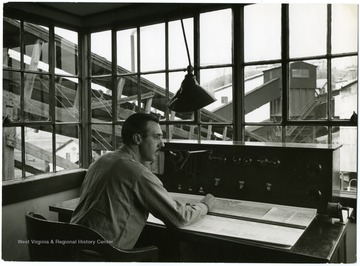

- Title:

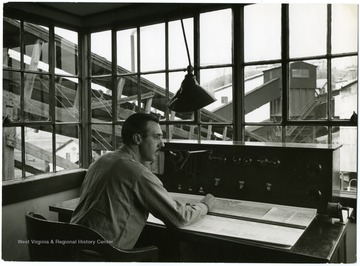

- Dispatcher at Mine No. 32

- Date:

- 1947

- Description:

- Dispatcher in office outside of mine. 'Credit must be given to William Vandivert, and picture is not to be reproduced without written license.'

- IDNO:

- 002996

- Title:

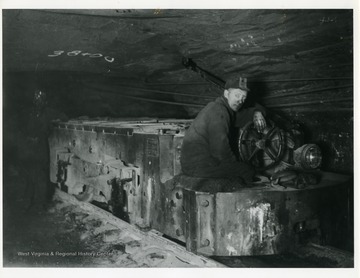

- Miner Operating an Electric Locomotive

- Description:

- 'An Electric Locomotive: Good dependable motive power is just as necessary in a coal mine as on a railroad. This picture shows on of White Oak's ten ton electric locomotives used to haul loads and distrubute empties in our mines. A crew consists of a motorman and brakeman, or trip rider, who pull loads from the working places to convenient sidings where they are picked up by main line locomotives, who haul to the tipple or shaft bottom. A large producing mine uses fifteen and twenty locomotives and five hundred mine cars in maintaining production.'

- IDNO:

- 003001

- Title:

- Miners Working with Loading Machine

- Date:

- 1959/04/07

- Description:

- Miners at work. 'Mountaineer Coal Co., Division of Consolidation Coal Co.'

- IDNO:

- 003002

- Title:

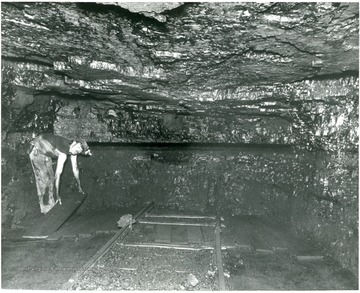

- Miner Placing Boards on the Floor of Cavalier Mine No. 206

- Description:

- Miner placing boards down near coal seam at Cavalier Mine No. 206.

- IDNO:

- 003003

- Title:

- Miner Working with Machinery Outside of Mine

- Description:

- A miner working with machinery on the exterior of a mine.

- IDNO:

- 003004

- Title:

- Railroad Car Loading Control Panel

- Description:

- Miner operating the Railroad car loading control panel.