Search Results

- IDNO:

- 003341

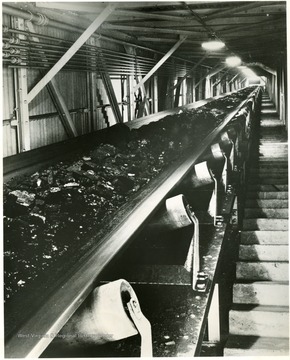

- Title:

- Raw Coal Conveyor Belt at Georgetown Preparation Plant

- Description:

- 'This enclosed raw coal conveyor belt starts the coal on its journey through the Georgetown Preparation Belt. The belt is 641 feet long and moves at a speed of just above 10 miles per hour. The coal is taken to the top of the plant, where it is given a preliminary sorting by size and then sent through one of the three cleaning circuits incorporated in the preparation system.'

- IDNO:

- 003343

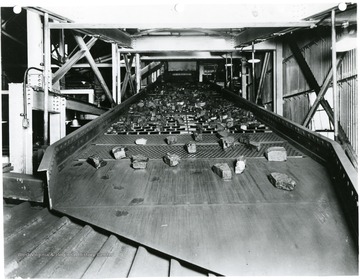

- Title:

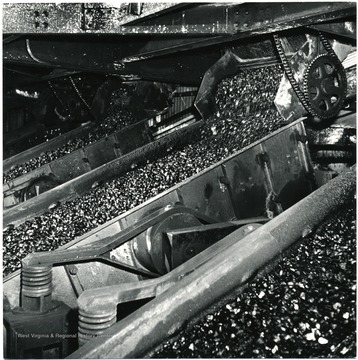

- Main Shaker Screen and Step Plate

- Description:

- Coal moves across the main shaker screen.

- IDNO:

- 003345

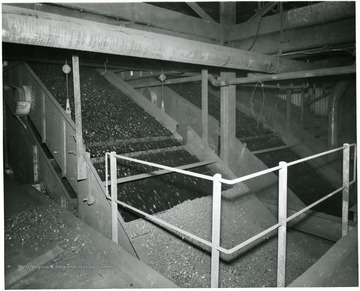

- Title:

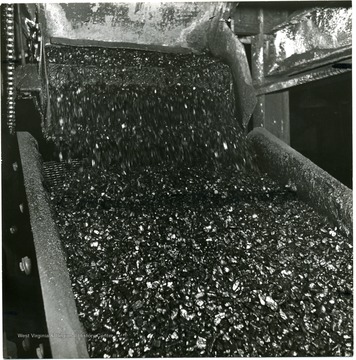

- Coal Being Processed

- Description:

- Coal traveling down a conveyors into bins.

- IDNO:

- 003346

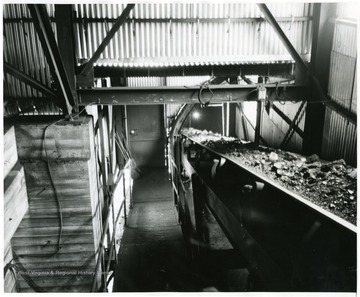

- Title:

- Stoker Coal at Williams Preparation Plant

- Description:

- Coal traveling down a conveyor for processing.

- IDNO:

- 003351

- Title:

- Conveyor Belt at Jamison No. 9

- Description:

- Coal traveling on a conveyor.

- IDNO:

- 003352

- Title:

- Coal Being Processed

- Date:

- 1947/07

- Description:

- Coal traveling on conveyors. Credit Must Be Given. Not to be reproduced without written license from William Vandivert.

- IDNO:

- 003353

- Title:

- Oil Treatment, Stoker Coal

- Date:

- 1947/07

- Description:

- Coal on a conveyor.

- IDNO:

- 003354

- Title:

- Interior of the Hutchinson Preparation Plant

- Description:

- Miner examines coal traveling down a conveyor inside the Hutchinson Preparation Plant, Pittsburgh Consolidation Coal Company.

- IDNO:

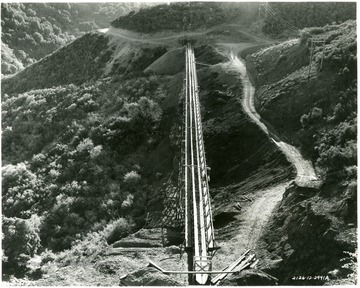

- 003366

- Title:

- Raw Coal Conveyor System

- Description:

- Conveyor belt in the middle of the mountains.

- IDNO:

- 003388

- Title:

- Sheltered Conveyor

- Description:

- 'A sheltered conveyor brings the Disco product from the carbonizers to this sheltered mechanical cooling wharf. A method of careful cooling in motion prevents spontaneous firing of the fuel and avoids injury to the structure of the product. The wharf is contructed of a series of grates, which are successively raised and lowered in a wavelike manner to keep the Disco product in motion and convey it slowly, while it is being cooled, down to the discharge end of the wharf.

- IDNO:

- 003393

- Title:

- Georgetown Preparation Plant

- Description:

- Georgetown Preparation Plant's raw coal conveyor and the refuse loading bin are shown in this picture.

- IDNO:

- 003422

- Title:

- Georgetown Preparation Plant

- Description:

- Looking down from top of a raw coal conveyor at receiving station.