Search Results

- IDNO:

- 003372

- Title:

- Ireland Mine Preparation Plant

- Description:

- 'The Plus 6" coal will be crushed to minus 1.5" and two 16,6" Chance Cones will wash the 6 x 3/8 coal. Current production of approximately 1800 tons per day is crushed to minus 1.25" then trucked to the storage yard of the new Kammer Power plant.'

- IDNO:

- 003373

- Title:

- Ireland Mine Machine Shop Fully Equipped

- Description:

- 'Two Joy 3-JCM and one Goodman 300 continuous miners are now in service producing coal. These machines have roof bolting machines as an integral part of their equipment. Two Joy 3-JCM machines are also being used brushing top and bottom where additional height is needed in the main haulage entries.'

- IDNO:

- 003374

- Title:

- Mine No. 155 Preparation Plant, Consolidation Coal Company, Van Lear, Kentucky

- IDNO:

- 003375

- Title:

- Ireland Mine Portal Area Supply Slope

- Date:

- 1958/06/01

- IDNO:

- 003376

- Title:

- Mathies Mine Preparation Plant

- Description:

- Coal buildings at the Mathies Mine, a division of Pittsburgh Consolidation Coal Co.

- IDNO:

- 003377

- Title:

- Mine No. 155 Tipple, Consolidation Coal Company, Van Lear, Kentucky

- Date:

- 1947/10/20

- IDNO:

- 003378

- Title:

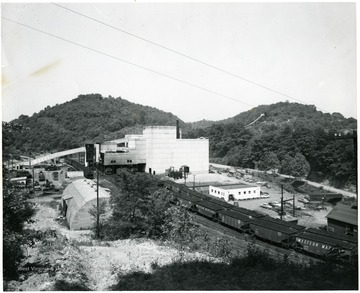

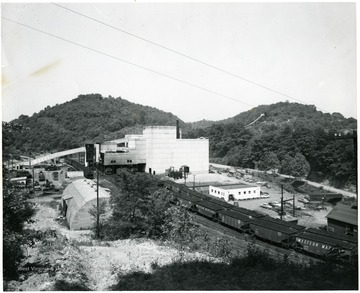

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Filled coal cars are lined up outside of the Williams Preparation Plant.

- IDNO:

- 003380

- Title:

- Georgetown Preparation Plant

- Description:

- Division of the Pittsburgh Consolidation Coal Co.

- IDNO:

- 003381

- Title:

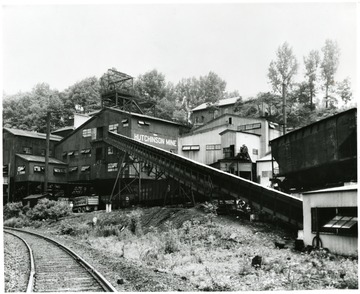

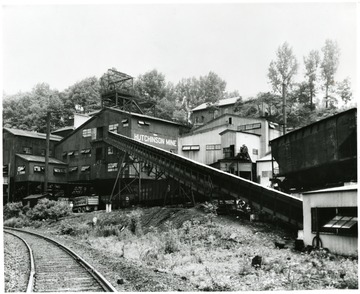

- Hutchinson Mine Preparation Plant

- Date:

- 1957/06/12

- Description:

- Mine cars and buildings around the preparation plant.

- IDNO:

- 003383

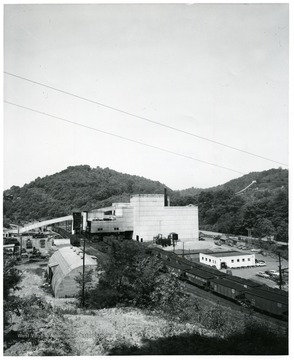

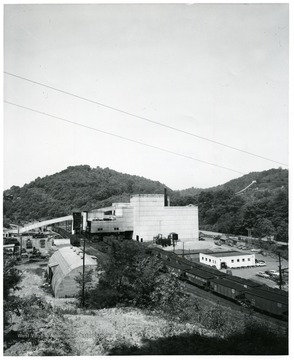

- Title:

- Hutchinson Mine Preparation Plant

- Date:

- 1957/06/10

- Description:

- Mine cars and buildings around the preparation plant.

- IDNO:

- 003385

- Title:

- Williams Preparation Plant, Consolidation Coal Company

- Description:

- Large preparation plant with filled coal cars lining the outside.

- IDNO:

- 003388

- Title:

- Sheltered Conveyor

- Description:

- 'A sheltered conveyor brings the Disco product from the carbonizers to this sheltered mechanical cooling wharf. A method of careful cooling in motion prevents spontaneous firing of the fuel and avoids injury to the structure of the product. The wharf is contructed of a series of grates, which are successively raised and lowered in a wavelike manner to keep the Disco product in motion and convey it slowly, while it is being cooled, down to the discharge end of the wharf.