Search Results

- IDNO:

- 003039

- Title:

- Control Board at Jamison No. 9

- Description:

- Miner at control board at Jamison No. 9.

- IDNO:

- 003040

- Title:

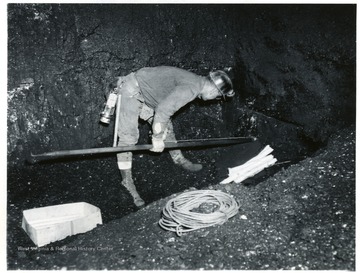

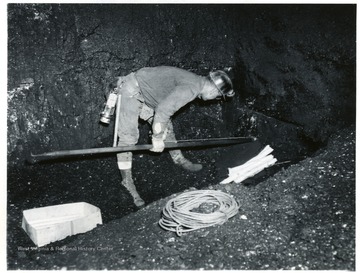

- Setting Explosives at Jamison No. 9

- Description:

- Miner setting charges at Jamison No. 9.

- IDNO:

- 003041

- Title:

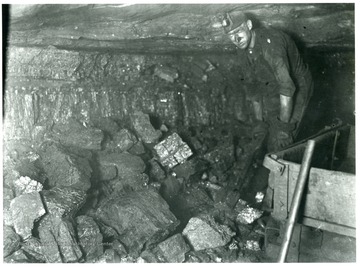

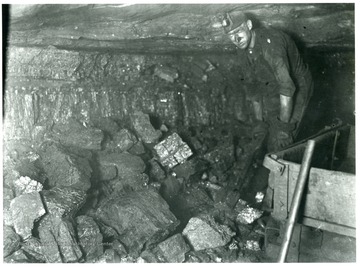

- Miner Loading Coarse Lumpy Coal

- Description:

- 'Coarse Lumpy Coal: This very coarse lumpy mine run coal is the result of proper shooting. The miner is paid on a tonnage basis for loading this coal into mine cars. He is required to watch his coal carefully as he loads it and she that no impurities become mixed with the coal.'

- IDNO:

- 003042

- Title:

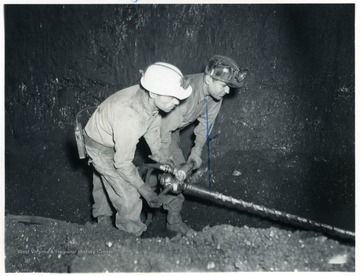

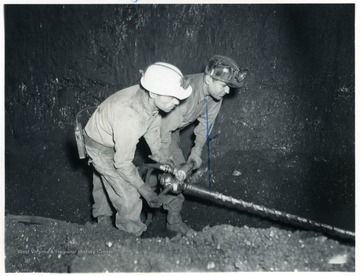

- Drilling Prior to Setting Explosives

- Description:

- Two miners drill before placing charges.

- IDNO:

- 003043

- Title:

- Joy Roof Bolt Drill at Jamison No. 9

- Description:

- Two miners work with a Joy roof bolt drill at Jamison No. 9.

- IDNO:

- 003044

- Title:

- Control Panel at Jamison No. 9

- Description:

- Miner works at the control panel at Jamison No. 9.

- IDNO:

- 003045

- Title:

- Jamison No. 9 Mine Locomotive

- Description:

- Miners ride in a locomotive at Jamison No. 9.

- IDNO:

- 003046

- Title:

- Jeffrey 290 cutting trench for 2200 volt line at Jamison No. 9

- Description:

- Jeffrey 290 cutting trench for 2200 volt line at Jamison No. 9. Stonega Coke and Coal.

- IDNO:

- 003047

- Title:

- Miner Operating a Loading Machine at Jamison No. 9

- Description:

- Miner using a 11 BU loading machine at Jamison No. 9. Stonega Coke and Coal.

- IDNO:

- 003048

- Title:

- Joy 10 RU Preparing to Cut US Royal Cable at Jamison No. 9

- Description:

- A Joy 10 RU preparing to cut US Royal Cable at Jamison No. 9. Stonega Coke and Coal.

- IDNO:

- 003049

- Title:

- Miner Operating a Cutting Machine

- Description:

- 'All White Oak mines are electrically equipped and of course this mining machine is operated by electricity. The machine is mounted and transported on a specially designed truck and moves under its own power from one working place to another. It is taken from the truck by the machine operator and his helper and moved to the place of the coal and placed in cutting position as you see in this picture. The machine consists of an endless chain with bits inserted, which act as cutters. The machine cuts a kerf or hole along the bottom of the coal about 4 feet and extending back six feet under the coal. The fine coal made by this machine is what is commonly known as bug dust. Cutting machines are operated at night and each machine is capable of cutting twenty places on each shift. These machines are operated on tonnage basis and these operators earn high wages.'

- IDNO:

- 003050

- Title:

- Continuous Mining Machine

- Date:

- undated

- Description:

- Miner running a continuous mining machine.